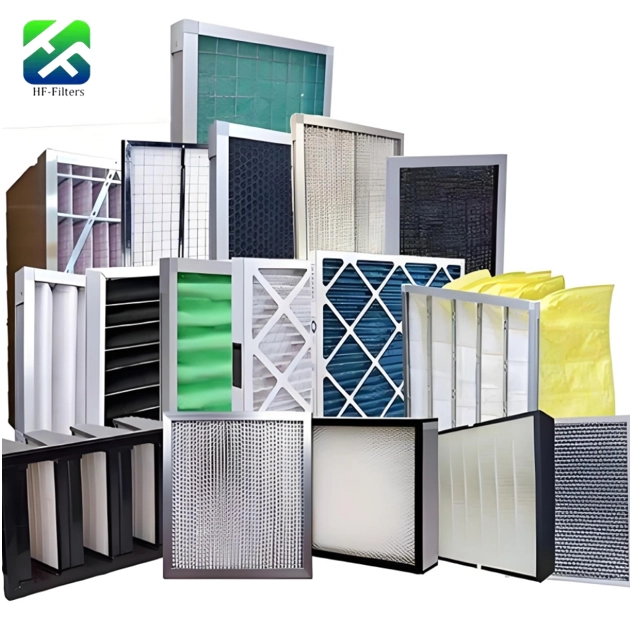

In 2025, every single project you touch feels like a fight. One consultant wants H14, another screams for MERV 15, and the third refuses anything except ePM1 numbers. Your inbox explodes, your engineers argue, and suddenly the job is late. Relax. One factory in Shenzhen has already fixed this mess for hundreds of buyers around the world. Healthy Filters started in 2016, runs its own 30 m³ cleanroom test lab, carries full ISO 9001, CE, and ROHS papers, and keeps real stock in Nashville, USA so you get filters in seven days instead of seven weeks. From hospital operating rooms to chip factories and green office towers, they simply send whatever standard the drawing asks for.

The Three Giants in 2025

Three big standards now control almost every commercial and industrial job on the planet.

True HEPA/ULPA (EN 1822)

This European test scans every single filter for leaks and guarantees H13 catches at least 99.995 % of the tiniest particles, H14 grabs 99.9995 %, and U15–U17 go even further. Doctors, drug makers and chip makers trust nothing else because lives and billion-dollar wafers are on the line.

MERV 11-16 (ASHRAE 52.2)

Across North America, building codes and insurance companies still speak only MERV. MERV 13 stops 90 % of particles between 1 and 3 μm, MERV 15 jumps over 95 %, and MERV 16 gets very close to real HEPA performance. Almost every LEED job and school project demands at least MERV 13.

ISO 16890 (ePM1/ePM2.5/ePM10)

Europe, China, Australia and most of Asia made the switch years ago. Instead of testing only at 0.3 μm, this standard measures how well a filter catches the actual dangerous dust people breathe every day: PM1, PM2.5 and PM10. An ePM1 70 % filter removes at least 70 % of the finest and most harmful particles.

2025 Buyer Behavior by Region & Application

Location and risk level decide everything for you.

North America & Middle East → MERV 13-15

More than two-thirds of all HVAC bids still list only MERV numbers because local rules, test labs and spare parts are built around it.

Europe & Asia → ISO 16890 mandatory

New laws in the EU and China GB/T 14295 force everyone to use ISO numbers. Nine out of ten fresh air-handling units ordered today in Berlin, Shanghai or Singapore carry ePM ratings.

Cleanrooms & Hospitals → Only HEPA/ULPA

No shortcut exists here. Operating theatres and ISO 14644 cleanrooms still demand scanned H13, H14 or ULPA filters, full stop.

Head-to-Head Performance Comparison

Fresh 2025 lab numbers make the differences crystal clear.

0.3 μm capture: ULPA > H14 > MERV 16 > ePM1 80 %

A U15 filter stops 99.9995 % of the most penetrating particles, H14 reaches 99.9995 %, MERV 16 lands around 99 %, while the best ePM1 80 % filter still lets 15–20 % slip through.

Energy cost: ISO 16890 wins 15-30 %

Thanks to clever V-bank shapes and lower average resistance, these filters need far less fan power over their whole life.

Filter lifespan: V-bank + ISO longest

Deep pleats and progressive media hold 600–800 g of dust per square metre, so the right ISO filter often runs 18–24 months while many flat MERV panels need changing every 9–12 months.

Healthy Filters’ 2025 Flagship Products

One single factory gives you perfect answers for every standard.

Custom V-Bank Box Filter → H13/H14/U15 HEPA/ULPA

Perfect for hospital ceiling units and semiconductor cleanrooms. You can pick gel-seal or knife-edge style, and every unit arrives with its own EN 1822 scan report so the validation team signs off the same day. The Custom Multi Function Compact Box Filters V-Bank Filter gives you full choice from H10 all the way to U15 in the same compact footprint.

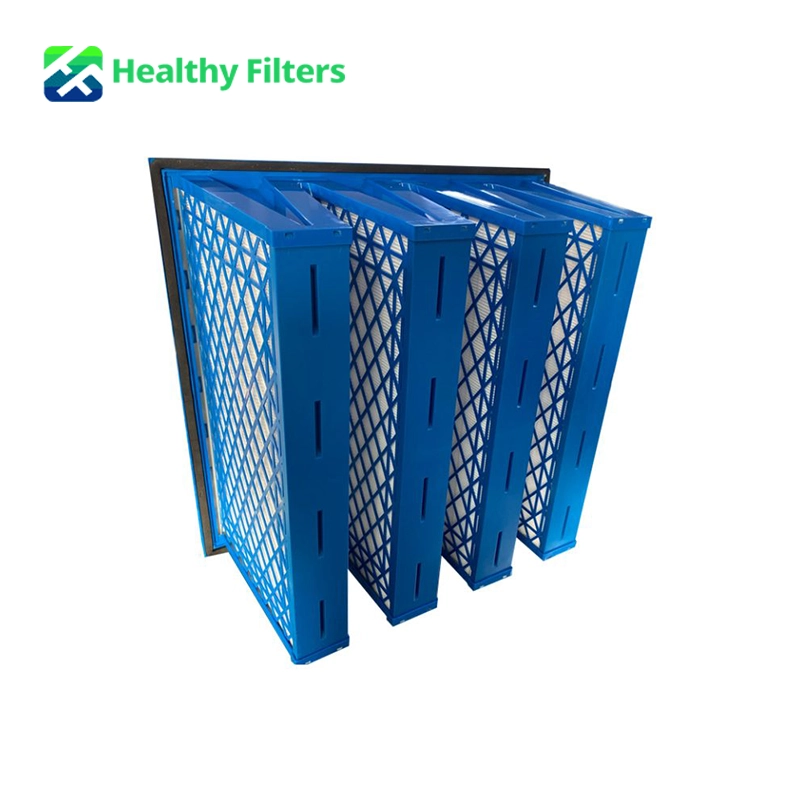

MERV 11-15 V-Bank Filter → North American bestseller

Strong ABS or galvanized frames plus tough PP/fiberglass media let these filters drop straight into nearly every American system with zero modifications. MERV 15 models stop more than 95 % of 0.3–1.0 μm particles and have become the top pick for schools, offices, and hospitals across the country. Click MERV ABS Galvanised Metal Frame PP Fiberglass to see why contractors keep reordering them.

Ultra-Compact Panel Filter → Pure ISO 16890 ePM1

Super-thin yet extremely powerful, this panel works great as a high-efficiency pre-filter or final filter when space is really tight. It delivers ePM1 70–80 % and ePM10 95 % while staying at only 25–35 Pa initial resistance, so fans stay quiet and energy bills stay low. Discover the full Ultra Compact Panel Filter that is winning tenders across Europe and Asia right now.

2025 Decision Matrix to Choose Which Standard

Three easy rules keep you out of trouble, and they save hours of meetings every week.

Use HEPA/ULPA for life-critical zones

If the room protects patients during surgery, produces medicine under GMP, or grows silicon wafers under ISO 14644, nothing except scanned H13, H14 or U15 is ever accepted. Engineers and regulators simply reject every other rating because even one missed particle can cost lives or millions of dollars.

Use MERV 13-16 for US/LEED projects

American codes, insurance forms and LEED checklists still ask for MERV numbers only. Pick MERV 13-16 and you stay legal, collect green-building points, keep the inspector happy, and avoid expensive change orders later.

Use ISO 16890 for lowest TCO & global tenders

When the job is in Europe, China, Australia or any country that cares about real PM1 and PM2.5 protection, write ePM1 65-80 % on the spec. You win more bids, pay 15-30 % less for electricity over the filter life, and change filters less often, so the building owner loves you.

Why Winners Source All Three from Healthy Filters

Top buyers hate dealing with three different suppliers, three sets of drawings, and three delivery dates.

Same factory, same V-bank footprint

Because the same production line makes H14, MERV 15 and ePM1 filters in identical V-bank boxes, you can swap one for another without touching a single duct or frame. The mechanical contractor finishes faster and the commissioning team has zero headaches.

60 % faster procurement

Send one purchase order, receive one set of certificates, pay one shipping bill, and clear customs once. Procurement teams report they cut filter sourcing time from six weeks to less than six days when everything comes from the same factory.

USA warehouse + 7-14 day delivery

Urgent hospital breakdown in California? Stock ships from Nashville in 48 hours. Big office tower in Dubai or Singapore? Fresh production leaves Shenzhen in ten to fourteen days and arrives before the old filters clog. One supplier, three standards, no panic.

FAQ

Q1: Can a MERV 16 filter replace H13 in an operating theatre?

A: No. Rules for hospitals and cleanrooms still demand leak-scanned H13 or H14 filters.

Q2: Is ePM1 70 % better than MERV 13 at catching fine dust?

A: Yes, it removes at least 70 % of particles from 0.1 to 1 μm while MERV 13 only manages 50–75 %.

Q3: Which standard saves the most electricity in normal office buildings?

A: ISO 16890 V-bank filters usually cut fan energy 15–30 % compared to similar MERV panels.

Q4: Do semiconductor cleanrooms ever accept only ISO 16890?

A: Never for the final filter. They may use ISO 16890 pre-filters, but terminal units must be EN 1822 HEPA/ULPA.

Q5: How quickly can one supplier ship certified H14, MERV 15 and ePM1 filters together?

A: USA stock ships in 48 hours; new production ships from China in 10–14 days. One box, three standards, zero headaches.