Preserving a very clean setting in advanced manufacturing demands a change from basic filtration to complete containment. In the semiconductor and electronics sectors, the gap between success and a failed batch usually rests on the seal quality between the filter and the ceiling grid. To protect your production standards, you require a partner with strong technical background. Healthy Filters, established in 2016 and approved by ISO9001, delivers fresh solutions from its modern CADR testing lab and uniform clean rooms. As a specialist in the area, they supply excellent OEM adaptability and tailored filtration plans that comply with CE, ROHS, and UL standards, which guarantees that your facility attains top air purity and operational steadiness via precisely built parts.

The Critical Challenge of Air Bypass in Semiconductor Cleanrooms

Cleanroom strength hinges on removing air bypass, which takes place when polluted air escapes around filter borders instead of flowing through the material. Even in sites equipped with efficient filters, a weak seal forms a direct route for particles to reach the clean area. This issue stands out sharply in major operations, where numerous filter units need to operate in full harmony.

Risks of Traditional Gasket Failures

Standard gaskets depend on physical pressure, which may turn irregular over time from frame twisting or shaking. Once a gasket forfeits its flexibility or holds a lasting shape, it produces tiny openings that undermine the whole cleanroom rating. These flaws permit contaminants to infiltrate, and they endanger the overall air quality in ways that demand constant vigilance.

Impact of Micro-Leakage on Product Yield

During chip production, particles below one micron trigger shorts on silicon wafers. Such unseen leaks cause instant yield reductions, and they injure the credibility of a production line by adding sporadic flaws to finished items. This outcome raises scrap rates, which in turn increases costs and disrupts schedules.

Complexity of Maintaining ISO Class 1 Standards

Attaining ISO Class 1 or Class 100 cleanliness offers zero margin for mistakes. Conventional sealing approaches call for regular torque tweaks and costly leak checks to uphold rules, which imposes heavy labor expenses on site oversight. These demands pull resources that could support other vital tasks.

The Engineering Superiority of Gel Seal HEPA Technology

Gel seal technology tackles the core drawbacks of mechanical pressure by employing a liquid sealing concept. A dedicated groove in the filter frame contains thick, non-Newtonian silicone gel, which forms a steady airtight seal when the housing blade sinks into it. This approach makes certain that air follows only the path through the filter material.

Zero-Leakage Performance via Fluid Sealing

The liquid quality of the gel enables it to cover all defects in the sealing face. In this way, it establishes a duplicate and reliable shield that outdoes any rigid gasket, thereby removing the chance of air bypass at the filter connection. This reliability sustains clean air flow even under demanding conditions.

Auto-Adjusting Sealing Property for Long-Term Stability

The gel stays flexible for many years, and it avoids drying or fading in sealing ability. Moreover, it shifts automatically to minor shifts in the structure or ceiling grid, which preserves an ideal seal without requiring hands-on fixes. This feature promotes enduring performance with minimal upkeep.

Superior Vibration Damping in High-Velocity Systems

Factory fans and Fan Filter Units (FFUs) produce ongoing vibrations that might slacken mechanical seals. The gel serves as a vibration absorber, which takes up mechanical force and blocks the spread of sound and motion to the cleanroom ceiling. Consequently, it bolsters the assembly’s firmness across extended periods.

Strategic Implementation of Gel Seal MERV Air Mini-Pleated HEPA Filters

For sites that demand total dependability, the Gel Seal MERV Air Mini-Pleated HEPA Filter delivers the strongest final filtration. These components are crafted for ceiling grids featuring a “knife-edge” frame, and they provide a smooth connection that assures the cleanliness of air reaching the work area.

Optimized Airflow Distribution through Mini-Pleat Design

Mini-pleat method enlarges the surface within a tight frame, which permits steadier air speed distribution. As a result, it lessens eddies in the cleanroom, an essential factor for upholding laminar flow above delicate equipment. This design enhances process control effectively.

High Efficiency Ratings for Sub-Micron Particle Capture

These filters achieve MERV 18 to 20 ratings, seizing 99.99% or higher of 0.3 micron particles. This accuracy proves crucial for blocking dirt on sensitive circuit assemblies. It safeguards product integrity throughout operations.

Seamless Integration into Standard Ceiling Grids

The uniform design confirms that these filters slot into present cleanroom structures with slight alterations. Therefore, they represent a prime option for fresh builds or revamps of aged facilities pursuing elevated cleanliness. Such compatibility eases adoption.

Supporting Cleanroom Integrity with Industrial HEPA H14 Pleated Air Filters

Outside the ceiling, targeted zones like dust collectors and specific machines seek dedicated safeguards. The Industrial HEPA H14 Pleated Air Filter is developed for these intense situations, offering a sturdy answer for devices that create their own particles or need a fixed stream of clean air.

Robust Construction for Heavy-Duty Industrial Use

These filters include strengthened frames and steady pleat intervals to endure elevated pressures in industrial outflow and input systems. They are made to retain form and performance amid nonstop duties. This durability suits harsh settings well.

Custom Sizing for Specialized Production Equipment

Electronics production frequently features distinct devices with irregular air entries. Tailored making enables coverage of your entire line with H14 performance, irrespective of the device’s initial layout or duration in service. It addresses varied requirements comprehensively.

Reliable H14 Efficiency for Fine Particulate Control

By securing H14 filtration at the device stage, you halt local dust from entering the broader cleanroom space. This action lightens the burden on the primary HVAC setup and prolongs terminal filter lifespan. Overall, it elevates environmental purity.

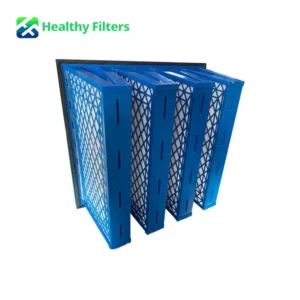

Maximizing HVAC Efficiency with V-Bank HEPA Air Filters

Overseeing a vast electronics plant involves equating large air turnover with power savings. V-Bank HEPA Air Filters stand as the top pick for core air units, since they furnish a much greater media area than usual flat types, enabling vast air passage with minimal opposition.

Enhanced Surface Area for High Airflow Capacity

The V-form arrangement packs additional filter media into the identical front space. Thus, it lets the HVAC deliver greater air volume without raising passage speed through the media, which heightens filtration results. This capacity meets intense demands reliably.

Reduced Energy Consumption through Low Resistance

Diminished air opposition signifies that input fans exert less effort to sustain needed turnover levels. Hence, it yields notable reductions in power expenses, a major element in the energy-heavy setting of a current plant. These gains accumulate steadily.

Durable Frame Options for Central HVAC Systems

Offered in options such as ABS or galvanized steel, these filters cope with central air challenges. They form a dependable shield versus external contaminants, confirming that incoming building air meets superior cleanliness. This preparation fosters consistent quality.

Secure Your Production Yield with Healthy Filters Expert Solutions

The intricacy of current electronics permits no filtration lapses. Collaborating with Healthy Filters secures entry to cutting-edge methods and a distributor system that aids your workflow persistence. Selecting capable gel seal and V-bank arrangements commits to your cleanroom’s lasting firmness and reliable output standards.

Global Expertise in Advanced Cleanroom Filtration

Extended research and growth in CADR testing labs have produced items aligning with strict global benchmarks. This knowledge facilitates guidance on optimal filtration phases for your particular production demands. It directs informed decisions effectively.

Comprehensive Quality Assurance and ISO Certification

All filters arise from rigorous quality controls and endure thorough exams prior to dispatch. You may trust the supplied specs, assured that every piece delivers its specified performance at setup. This assurance underpins dependable deployment.

Reliable Partnership through our Global Distributor Network

Swift availability of substitute filters and expert aid proves essential for curbing interruptions. An extensive system guarantees that for routine enhancements or sudden swaps, required elements arrive promptly to sustain your site’s function. It upholds seamless activity.

FAQ

Q1: What makes a gel seal better than a standard gasket?

A: A gel seal offers a liquid, airtight shield that occupies every flaw in the sealing face, while a gasket depends on mechanical pressure that might collapse under irregular force or material wear.

Q2: Can I use H14 pleated filters in high-temperature environments?

A: Yes, select pleated filters incorporate heat-tolerant materials and frames to preserve H14 performance in targeted industrial tasks.

Q3: Do V-Bank filters require special housings for installation?

A: V-Bank filters typically align with standard 24×24 inch HVAC frames, positioning them as effective substitutes for numerous core air configurations.

Q4: How does the gel in the filter react to chemical cleaners?

A: The thick silicone gel in these filters remains chemically firm and withstands typical cleanroom sanitizers, preventing breakdown in standard maintenance.

Q5: Are custom OEM sizes available for all HEPA filter types?

A: Yes, bespoke dimensions and arrangements exist for pleated, gel seal, and V-bank filters to secure ideal matches for irregular devices and distinct site designs.