Keeping good air quality is a basic need in today’s food production. More than just collecting dust, managing volatile organic compounds and lasting smells is key to guarding both the goods and the company name. Picking the right filter material means weighing how well it holds gases, how much it blocks airflow, and how it stands up to tough conditions. If you want a steady supplier in this area, Healthy Filters comes up as a leading maker focused on strong air cleaning. With a firm hold on a company culture of fresh ideas and solid work, they provide full solutions for various factory demands. Their worldwide distributor setup makes sure plants everywhere can get pro-level filter tech built for long use and good results.

Importance of Air Quality in Food Processing

Air in a factory space can help keep stock safe or make it go bad, and strong air control is not just a choice but a core part of any plant that wants to last and stay safe.

Regulatory Safety Compliance

Food safety groups demand close following of clean rules to stop germ and dust spread. Right filtering helps your plant meet these strict laws and skips big fines or shutdowns.

Product Flavor Integrity

Food items react strongly to nearby smells, so solid air cleaning stops mix-up between lines and keeps the fine taste of your goods steady without marks from close work.

Employee Workplace Wellness

Thick food smells and gas fumes can cause unease or breathing problems for workers, and using better smell control setups makes a safer job spot, cuts tiredness, and boosts daily work flow.

Shelf Life Preservation

Air dirt often brings germs that speed up rot, but clearing these bits and gas pollutants can greatly lengthen how fresh and stable your packed items stay.

Common Filter Materials for Odor Mitigation

Removing smells works on sticking molecules instead of basic pulling through mesh, and various materials give different levels of work based on the makeup of the smell particles.

Activated Carbon Media

Activated carbon is the go-to choice for gas cleaning in the field. Its hole-filled build offers a huge area to catch volatile organic compounds (VOCs) and usual food work smells such as oil or brew gases.

Impregnated Chemical Fibers

For certain sour or base gases, carbon material gets coated with chemical helpers, and these treated fibers cancel smells via a sticking reaction called chemisorption, which works better for set factory outputs.

Composite Synthetic Layers

Mixed materials join particle pulling with slim carbon sheets, and they fit spots with both dust and mild smells, giving a compact fix for multi-step air units.

Specialized Glass Microfiber

Dense glass threads are vital for grabbing tiny drops and bits that carry smells, and though they do not stick gases right away, they clear the main holders of many sharp food scents.

Effective Applications for Different Food Environments

Each part of a Food Processing Plant needs a custom filter plan to handle set issues like warmth, wetness, or top clean needs.

High Temperature Processing Zones

In spots like big ovens or fry areas, regular filters might break from heat strain, but a High Temperature HEPA Industrial Filter keeps air clear of fine smoke and bits even in harsh heat without harming the filter frame or material.

Sterile Aseptic Packaging Lines

At the end packing steps, you have to wipe out all risks, and a Cleanroom HEPA Air Filter gives the needed H13 or H14 work to make a local super-clean zone that guards food right before sealing.

General Raw Material Storage

Storage zones gain from steady air flow to avoid buildup of old smells or damp scents, and basic vent filters with strong dust hold work best here to shield large stock from falling dirt.

Commercial Baking and Frying

Baking and frying put out lots of oil spray and organic fumes, so a tough setup with a 4V V Bank Activated Carbon Air Filter fits well, as the V-bank shape allows big air flow while giving the most carbon area to clean smells from vent or reused air.

Key Products from Healthy Filters for Industry Use

Picking the proper gear makes sure filter gains show up in your routine tasks, and these set tools are made to fit smooth into pro air systems.

4V V-Bank Activated Carbon Filter

This setup is built just for large air lines where smell clear is key, and the plastic or metal frame keeps several carbon sheets in a V form to boost time air touches the sticking material.

Cleanroom HEPA Air Filter Series

These filters get checked to hit tight H13 and H14 rules, and they form the last wall against tiny germs and fine dust, which makes them a must for touchy food areas needing clinic-level clean.

High Temperature HEPA Industrial Filter

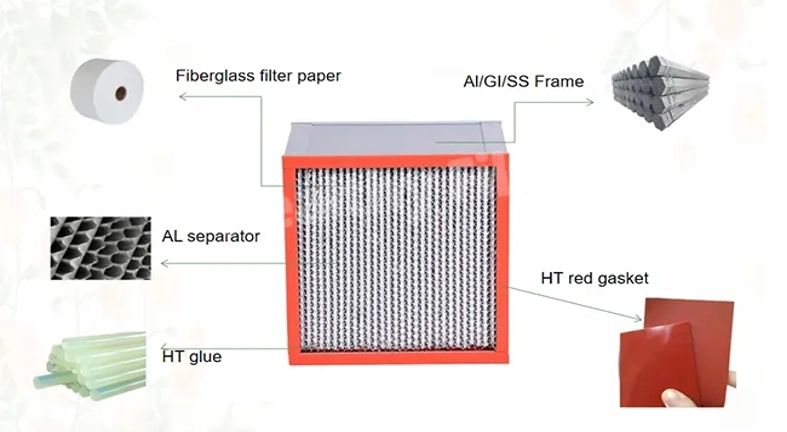

With glass fiber material and special heat sealants, these parts hold form and work at heats up to 250°C or more, and they lead as the top pick for hot air loops in food making.

Integrated Food Plant Solutions

Full filtering uses a multi-step method, starting with early filters for big junk and ending with HEPA or carbon steps, which keeps the whole setup lasting and air as pure as possible.

Professional Advantages of Healthy Filters

Choosing a provider with tech know-how means you get items that work as said in real settings, and pro making skills turn straight into safety on your food line.

Advanced Manufacturing Expertise

Smart build methods let makers create filters with less air block and better work, and this skill brings power cuts to your plant since fans push less hard through the material.

Global Distribution Support

Solid shipping and partner links mean swap filters arrive when needed, and sticking to a firm change plan gets easier with a steady and quick supply line.

Customizable Filtration Solutions

Not all food plants have the same design, so the chance to order set sizes and frame types like steel for wash zones makes sure the filter system matches your build and clean rules.

Commitment to Quality Standards

Hard checks under world rules like EN1822 or ISO 16890 make sure each filter gives the guard listed, and this clear view builds faith and keeps your plant in line with global food checks.

FAQ

Q1: Can HEPA filters remove cooking smells directly?

A: HEPA filters aim to grab bits and germs; while they clear smell-carrying particles, pair them with activated carbon to handle gas smells well.

Q2: What is the benefit of a V-bank design for carbon filters?

A: The V-bank form boosts the material area a lot, which lets higher air speed and longer touch time without making the filter bigger.

Q3: Are high-temperature filters necessary for all baking areas?

A: They matter if filters sit right in heat flow or vent where temps pass limits of regular plastic or glue seals.

Q4: Do these filters help in reducing cross-contamination between spicy and sweet production lines?

A: Yes, high-work carbon cleaning in air reuse setups can wipe out the gas taste bits that lead to flavor mix.