Clean air pushes factories to do well. Little bits of dirt, too small to see, hurt the things you make. They also make workers sick and break rules. HEPA filters grab 99.97% of bits down to 0.3 microns. ULPA filters work harder. They catch 99.999% at 0.12 microns. These tools guard special places. Think electronics plants, medicine labs, and big air systems in stores. More factories want them now. They need exact work and safe spots.

Healthy Filters started in 2016 in Shenzhen. It gives plans that fit just right. The shop follows ISO9001 rules. It has a big 30-cubic-meter CADR test room. You can get help all over the world through sellers. This story shows why these filters count. It tells how certain items fix your problems.

What Are HEPA and ULPA Filters?

You meet flying dirt all the time in factory rooms. HEPA and ULPA filters stand as your main guard. These parts follow hard rules like EN 1822. So, they give steady work even when things get tough.

Basic Definitions and Standards

HEPA gets 99.97% clean at 0.3 microns. It uses the hardest bit size test. ULPA hits 99.999% at 0.12 microns. Marks like CE, ROHS, and SGS prove they work.

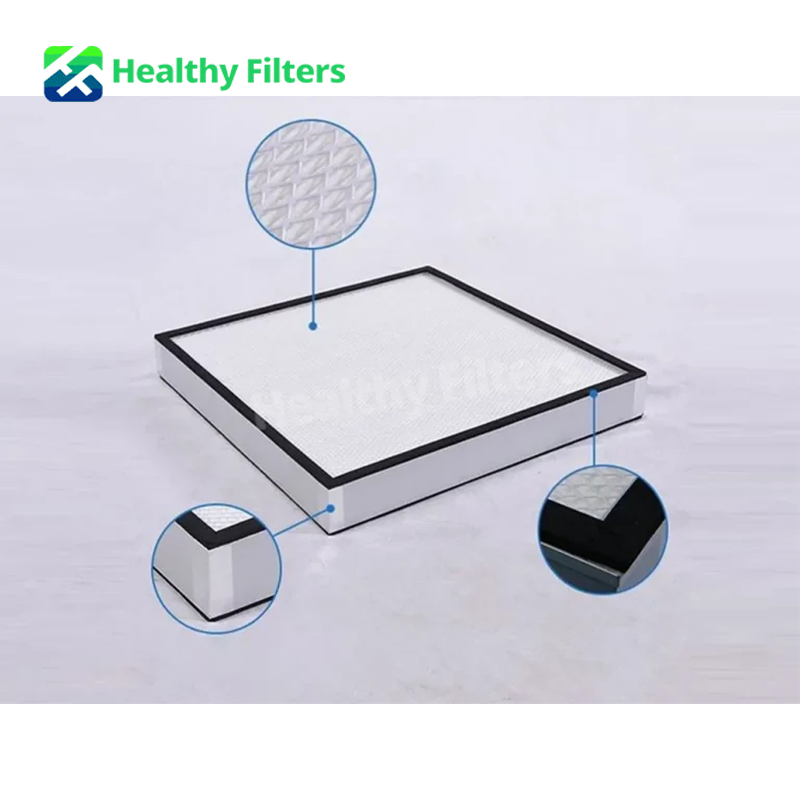

Key Components and Materials

Many layers use polypropylene or fiberglass stuff. Strong edges, mostly aluminum, hold gel seals. This stops leaks. Big dirt hold keeps them going longer.

Common Industrial Uses

Clean rooms, FFU boxes, and dirt catchers need these filters. They keep air pure in electronics and medicine spots. Even one small bit can cost a lot of money.

Why Do Industries Need HEPA and ULPA?

Bad stuff hides all over your shop. Dust, tiny bugs, and smelly air hurt work. Rules say you must act. These filters give rule follow and extra good work.

Health and Safety Regulations

OSHA and ISO rules want tight air checks. Miss them and pay big money or close. HEPA and ULPA reach H13 to U15 levels. They pass the hardest checks.

Contaminant Removal Benefits

They catch sneeze makers, bugs, and super small bits. Many layers take heavy dirty loads. Your team breathes easy. Fewer sick days come.

Operational Efficiency Gains

Pure air saves delicate machines. Machines last longer. You spend less on fixes. Start pressure drop stays low, often below 250 Pa. Power bills drop too.

How Do HEPA and ULPA Enhance Air Quality?

Your air movers push huge wind every day. Top cleaning keeps things pure. It does not slow speed. Ways join to give steady wins.

Particle Capture Mechanisms

Spreading slows tiny bits. Catching holds middle ones. Hitting stops big junk. All together, they get almost all gone.

Adaptation to High Temperature Environment

Some stand heat to 250°C or 350°C. They take set wind from 900 to 3650 m³/h. Gel seals block side leaks in shaky spots.

Long-Term Air Purity Maintenance

Dirt hold hits 600 g/m² in first filters. End push stays at 450 Pa top. Change less. You save time and cash.

What Risks Arise Without Proper Filtration?

Skip good cleaning and ask for trouble. Bad goods stack up. Sick calls grow. Law problems come next. Real hits hurt your cash hard.

Product Contamination Issues

One lost bit wrecks whole groups in electronics or medicine. Call backs kill good name. The Liquid Tank Sealed Fine Efficiency Air Filter stops this. It uses locked many-layer guard.

Worker Health Hazards

Breathing trouble jumps without pure air. Workers miss more. Happy feelings fall. Keep your crew safe with sure tools that beat simple needs.

Financial and Legal Penalties

Rule break cash adds quick. Safe pay jumps after bad events. Put money in trust to skip these hide costs full.

How to Select the Best HEPA or ULPA System?

Picks confuse without clear marks. Fit details to your wants. Change plans make sure perfect match for any job.

Efficiency and Rating Evaluation

Check needed steps: H14 for most factory jobs, U15 for super clean rooms. Test at 0.25 to 1.12 m/s wind. Clean space counts, from 2.8 to 33.84 m².

Customization for Specific Applications

Change sizes like 610x610x292 mm. Pick fold or mini fold styles. The Custom Industrial HEPA H14 Pleated Air Filter fits FFU boxes just right.

Cost-Effectiveness Analysis

Count all own costs. Add change times and power use. Better start quality gives back with longer work life.

What Solutions Provide Optimal Industrial Filtration?

Plain filters fail in hard spots. Special plans fix set troubles. Three top picks meet usual hurts.

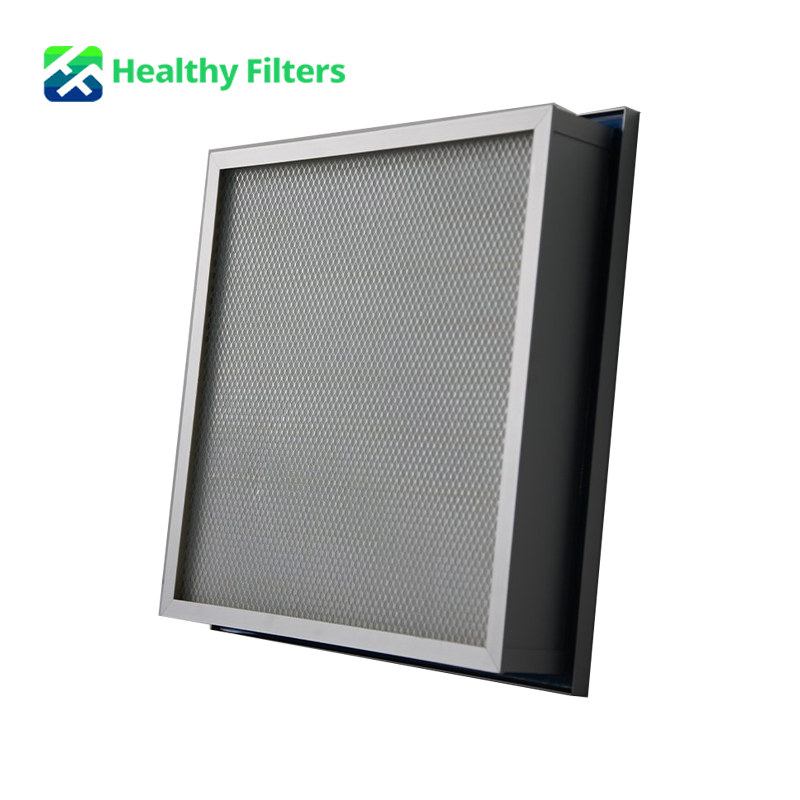

Sealed Liquid Tank Designs

No leak build with PU glue. Many layer stuff takes store loads. Sizes from 346x346x69 mm give 300 m³/h fast.

Pleated HEPA Customizations

H14 clean in small shapes. Clean space to 33.84 m². Great for dirt catchers and electronics plants that want exact rule.

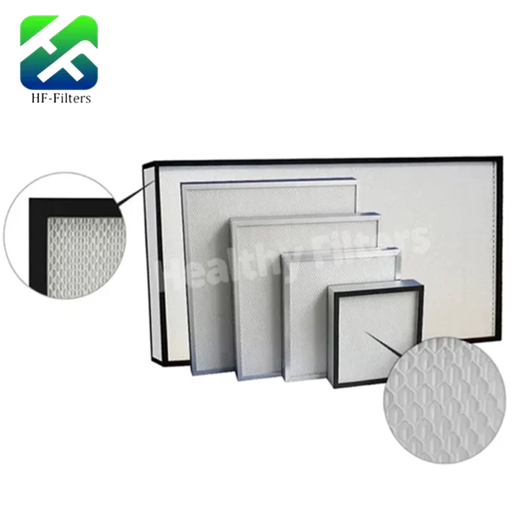

Mini Pleat Panel Innovations

U15/H14 steps with gel seals. Shiny aluminum edges fight rust. The Mini Pleat Panel Filter shines in clean room ends.

Why Choose Healthy Filters for Your Needs?

Know-how counts when much is on line. Sure past makes trust. Full help makes buying easy.

Proven Industry Expertise

Years of special making. Top test rooms. World marks promise same good in every group.

Comprehensive Product Range

From first filters to ULPA tools. Cover all clean steps. Find fixes for any factory air fight.

Customer Support Excellence

Quick send from USA store. Tech talk ready. Grow strong ties that build with your shop.

FAQ

Q1: What efficiency levels do HEPA and ULPA filters achieve?

A: HEPA grabs 99.97% of bits as small as 0.3 microns. ULPA takes away 99.999% at 0.12 microns. Both hit H13 to U15 marks.

Q2: How often should industrial air filters be replaced?

A: Change them based on dirt buildup and end pressure drop. This usually happens every 6-12 months. Watch when resistance hits 450 Pa at most.

Q3: Can these filters handle high temperatures?

A: Some types stand heat up to 250°C or 350°C. Fiberglass stuff stays strong in rough spots, and it keeps working great.

Q4: What makes gel seal designs superior for cleanrooms?

A: Gel seals stop leaks completely. Anodized aluminum frames fight rust and stay firm.

Q5: How do pleated designs improve airflow performance?

A: Bigger media space, up to 33.84 m², lets more air move with less push. So, you save power, and cleaning stays top-notch.