Ventilation systems in commercial buildings, industrial facilities, hospitals, and food processing plants often deal with odors, volatile organic compounds, and harmful gases. Reliable carbon air filters remove these pollutants effectively and ensure compliance with air quality standards. Prices vary widely based on design, carbon load, size, and performance requirements. You need filters that balance upfront cost with long-term efficiency and durability.

For proven solutions, turn to Healthy Filters, a Shenzhen-based manufacturer founded in 2016 that specializes in air filtration for ventilation and cleanroom applications. The company produces a wide range of activated carbon filters alongside HEPA and pre-filters, all backed by ISO9001 certification and approvals including CE, ROHS, SGS, FCC, ETL, and UL. Advanced production and a 30-cubic-meter CADR testing center guarantee consistent quality. With an overseas warehouse in Nashua, USA, delivery reaches North America quickly. Healthy Filters excels in OEM and custom projects, making it a dependable partner for ventilation system upgrades.

Factors That Determine Carbon Air Filter Prices

Several elements influence the final cost of carbon air filters for ventilation systems. Quality choices in these areas directly affect performance and lifespan.

Filter Type and Design

Panel filters with folded media offer basic odor control at lower cost. Pocket or bag designs increase surface area and carbon volume for better adsorption in medium-duty applications. V-bank configurations provide the highest capacity and longest contact time, ideal for large airflow systems. Honeycomb or granular structures also impact efficiency and price.

Carbon Quality and Quantity

Higher-grade coconut shell or columnar activated carbon delivers superior adsorption of benzene, formaldehyde, and odors. Filters with greater carbon weight per square meter, such as 200g/m² or more, cost more initially but last longer. Powdered carbon in sandwich media combines dust collection with gas removal effectively.

Size and Airflow Capacity

Standard sizes like 592x592x300mm suit common ducts, while custom dimensions raise costs. Filters rated for 2000 to 4000 m³/h airflow require more material and robust frames, increasing price accordingly.

Frame Material and Build Quality

Galvanized steel or aluminum alloy frames resist corrosion in humid environments. Cardboard options reduce weight and cost for lighter applications. Ultrasonic sealing and reinforced construction add durability and justify higher investment.

Average Price Ranges for Different Carbon Air Filter Types

Current market prices in 2026 reflect material costs, manufacturing standards, and performance levels. Expect variation based on order volume and specifications.

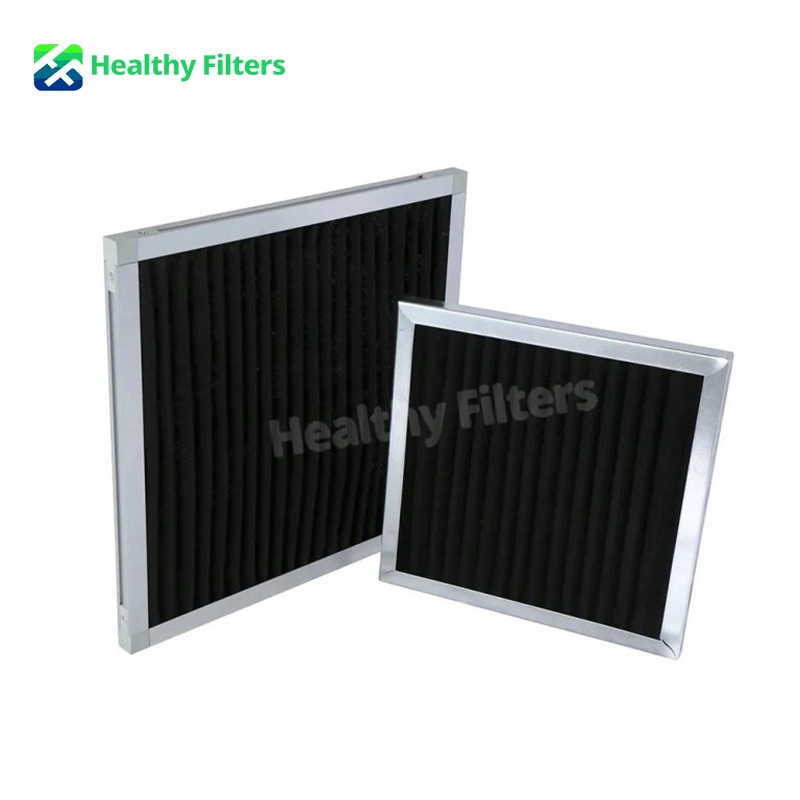

Primary Efficiency Carbon Panel Filters

These pleated panels serve as pre-filters with activated carbon media in G3 or G4 classes. Typical sizes range from 290x595x46mm to full 592x592mm. Prices generally fall between $5 and $20 per unit, depending on carbon content and folding density.

The Primary Efficiency Activated Carbon Pre Air Filter uses aluminum separators or cardboard honeycomb for structural support and efficient odor removal in ventilation inlets.

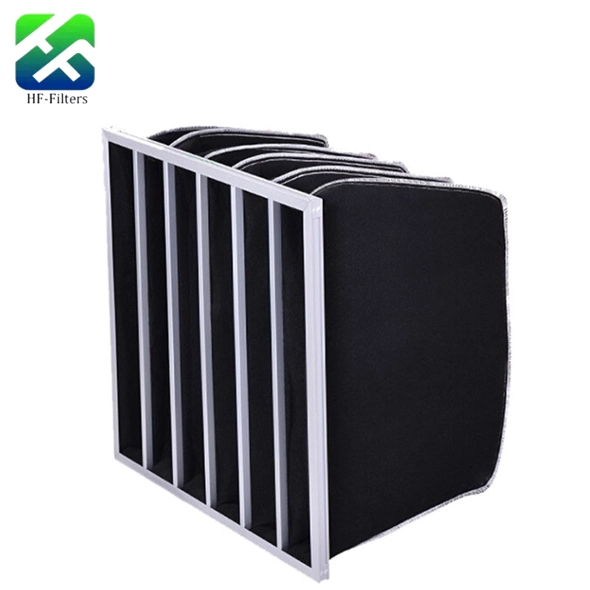

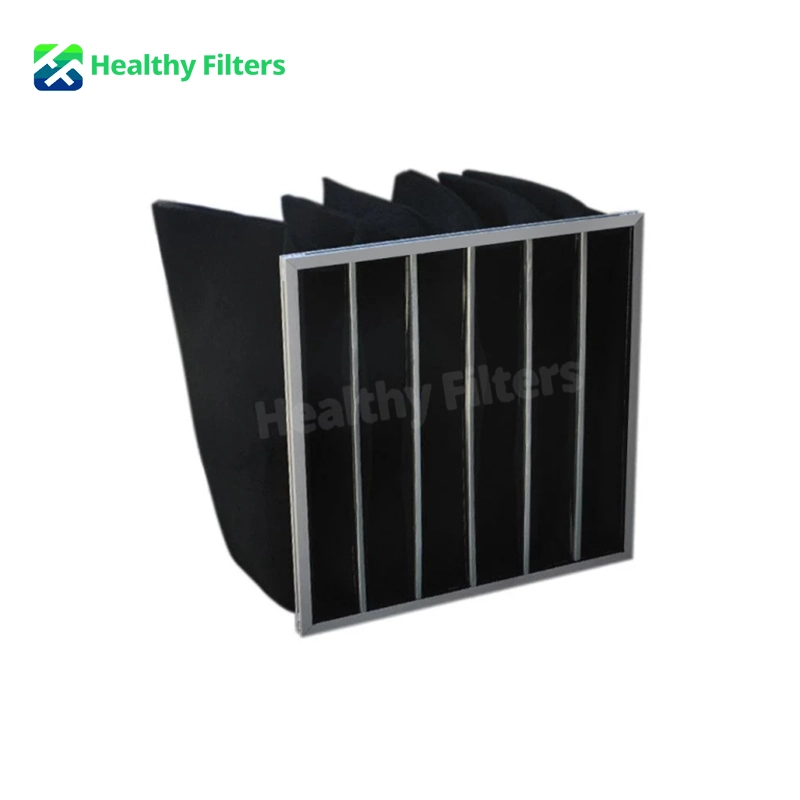

Pocket and Bag Style Carbon Filters

Industrial pocket bags combine primary efficiency with activated carbon for grease and odor capture in kitchen exhaust or factory ventilation. Larger surface area extends service life. Prices range from $20 to $40 per filter, influenced by pocket count and carbon load.

V-Bank and High-Capacity Carbon Filters

V-bank designs handle high airflow with minimal pressure drop. Galvanized frames and granular carbon filling target demanding environments like hospitals and electronics plants. These units cost $50 to $100 each, reflecting greater carbon volume and engineering.

The 4V V Bank Activated Carbon Air Filter provides robust construction for large-scale odor control.

Cost Comparison and Long-Term Value

Upfront price tells only part of the story. Total ownership cost includes replacement frequency, energy use, and system protection.

Initial Purchase Price vs Replacement Frequency

Higher-quality carbon filters with dense media and premium granules adsorb more pollutants before saturation. This extends intervals between changes, often to 6-12 months instead of 3-4 months for cheaper options, lowering annual expenses.

Energy Savings from Low Pressure Drop Designs

Filters with optimized airflow paths maintain lower resistance. V-bank and well-structured pocket designs reduce fan energy consumption, delivering savings that offset higher initial costs over time.

Performance and Odor Removal Effectiveness

Effective removal of benzene, formaldehyde, and hydrogen sulfide prevents complaints and ensures regulatory compliance. Reliable adsorption prevents breakthrough and maintains consistent air quality.

The Industrial Primary Activated Carbon Pocket Bag excels in industrial settings for sustained odor elimination.

Recommended Reliable Carbon Air Filters for Ventilation Systems

Choose filters that match your airflow, pollutant load, and installation requirements.

Primary Efficiency Activated Carbon Panel Filters

These panels integrate easily into existing HVAC units and provide cost-effective first-stage gas removal alongside particulate capture.

Industrial Primary Activated Carbon Pocket Bags

Pocket designs suit kitchen exhaust, painting booths, and general ventilation where grease combines with odors.

4V V-Bank Activated Carbon Filters

These units deliver maximum contact time and capacity for central systems in large facilities.

Why Healthy Filters Offers the Best Value in Carbon Air Filtration

Healthy Filters delivers exactly your expectation through disciplined manufacturing and customer-focused service.

Competitive Pricing with Premium Quality

Healthy Filters maintains direct control over production, from raw activated carbon selection to final assembly. The company uses high-grade coconut shell carbon and columnar granules that achieve strong benzene adsorption rates above 70%. Robust testing in a 30-cubic-meter CADR center ensures every filter meets advertised performance. ISO9001 certification and approvals including CE, ROHS, SGS, FCC, ETL, and UL confirm consistent standards. These factors allow competitive unit prices while avoiding the quality compromises common in lower-cost alternatives.

Customization and OEM Capabilities

Ventilation projects often require specific sizes, carbon loads, frame materials, or combined media. Healthy Filters excels in OEM and ODM work, producing tailored panel, pocket, or V-bank carbon filters to match exact airflow and installation needs. Options include aluminum alloy separators, galvanized frames, cardboard honeycomb structures, or varying carbon weights from 180g/m² upward. Low minimum orders and rapid prototyping reduce risk for system designers and contractors.

Global Support and Fast Delivery

An overseas warehouse in Nashua, USA, stocks popular carbon filter models for immediate shipment across North America. Direct factory supply serves Europe, Southeast Asia, and other regions efficiently. Technical support covers selection, installation guidance, and performance validation. This network minimizes downtime and simplifies procurement for large facilities or multi-site projects. Healthy Filters builds long-term partnerships by combining quality, flexibility, and reliable logistics.

FAQ

Q1: What affects the price of carbon air filters most?

A: Carbon quantity, filter design complexity, size, and frame material drive costs, with V-bank types being the most expensive due to higher capacity.

Q2: Are more expensive carbon filters worth the investment?

A: Yes, premium filters reduce replacement frequency and energy costs while providing better odor and VOC removal.

Q3: Can primary efficiency carbon filters handle strong odors alone?

A: They work well for mild to moderate odors as pre-filters, but heavy loads often require V-bank or dedicated carbon stages.