Clean air is no longer something you can take for granted. Dust, smoke, pollen, and even germs float around in every space where people live or work. The smallest particles, often invisible to your eyes, can cause breathing issues, allergies, or worse. For many, the only real way to keep the air safe is to use a high efficiency particulate air filter. If you are looking for a trusted source, Healthy Filters stands out. This company, founded in 2016 in Shenzhen, China, produces a wide range of air filters and purification products. They carry HEPA filters, ULPA filters, activated carbon filters, humidifier filters, and many replacement units. Their factory is certified by ISO9001 and their products meet CE, ROHS, SGS, FCC, ETL, and UL standards. They also have a CADR testing center and clean rooms that match strict industry rules. With a warehouse in Nashua, USA, delivery to North America is much faster, often just a few days. Their service also includes OEM solutions, so if you need custom filters or special sizes, they can build them.

What Makes HEPA Filters Stand Out From Other Filters?

Pre-filters may catch larger dust and hair, but they often fail when the particles are too fine. HEPA filters are designed differently. They use advanced media with fibers set at random angles, creating many layers of trap points. This structure gives them the power to catch even the most stubborn airborne particles. That is why they are considered vital in hospitals, labs, and industries.

Filtration Efficiency at 99.97% and Beyond

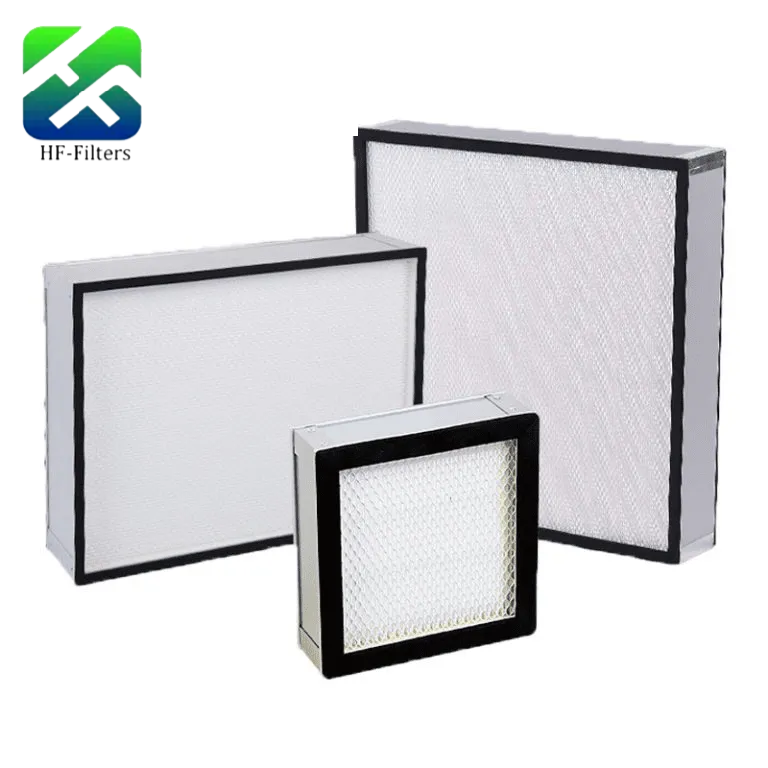

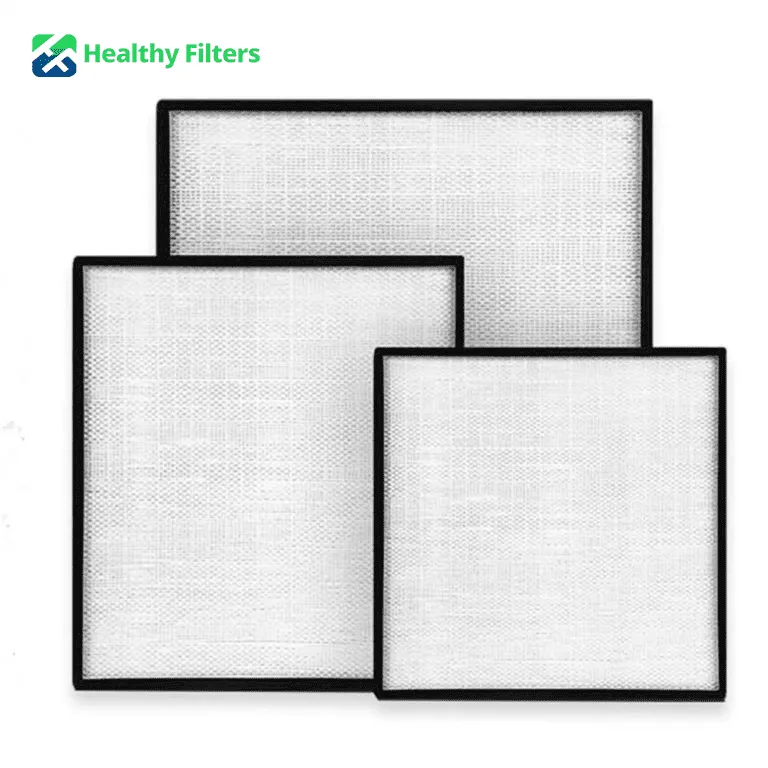

HEPA grades H13 and H14 are tested to remove nearly every particle in the size range that is hardest to stop. This can mean blocking up to 99.99% of dust and spores. The Customized Industry and Clean Room Use H13 H14 Cleanroom HEPA Air Filter shows this in action. Think about a pharmaceutical plant, where a small amount of powder or bacteria could spoil an entire line of medicine. Using this filter makes it possible to keep the air clean enough for production.

Ability to Capture Ultra-Fine 0.1 Micron Particles

Not all harmful particles stop at 0.3 microns. Many microbes and smoke particles are even smaller. That is why filters like the Healthy Filters Customized 0.1um HEPA Separated High Efficiency Air Filter H13 Large Merv 18 U15 exist. With a deep pleated design and high standards, it can trap particles down to 0.1 micron. This level of performance is what electronics factories and clean labs count on. Without it, tiny particles could ruin circuits or contaminate tests.

Why Are HEPA Filters Essential for Cleanroom and Industrial Applications?

Industries and cleanrooms cannot risk even minor pollution. The wrong particle in the wrong place could shut down a machine or damage products worth millions. HEPA filters solve this by keeping the air controlled and stable.

Reliable Solution for Electronics and Pharmaceutical Industries

Electronics factories need strict air quality. Dust on a wafer can destroy microchips. In drug production, contamination can lead to unsafe medicine. High grade H13 and H14 cleanroom filters work as the final barrier, catching almost all dangerous particles before they reach the critical zone.

Consistent Air Quality in Controlled Environments

Filters like these are tested to hold their efficiency for long periods. In hospitals, they help keep surgery rooms sterile. In labs, they support experiments that cannot afford outside influence. Consistent performance is often more important than peak numbers. After all, no one wants a filter that works for a month and then fails.

Custom Sizes and OEM Flexibility for Project Needs

Every building and machine has different ducts or housings. Off-the-shelf filters do not always fit. OEM flexibility allows you to order exact sizes and shapes. This helps you avoid costly redesigns. For engineers running projects, this service reduces stress and saves time.

How Do HEPA Filters Protect Human Health?

Indoor air quality often feels worse than outside. Furniture, paint, pets, and people all add particles into the air. HEPA filters target this hidden pollution and protect you from it.

Removal of Allergens and Airborne Dust

For people with asthma or allergies, airborne dust and pollen are constant problems. With HEPA filters in your air system, these allergens are trapped. Families often report fewer sneezes, less eye irritation, and easier sleep.

Barrier Against Bacteria and Viruses

In hospitals, airborne bacteria can spread infections quickly. HEPA filters reduce this risk. They capture droplets that carry viruses. This is why many isolation rooms are equipped with such systems.

Cleaner Indoor Air for Homes, Offices, and Hospitals

Even in regular offices, cleaner air improves comfort. Studies show that poor indoor air leads to more sick days. With HEPA filters in place, workers stay healthier. In homes, children and elderly people benefit most, as they are often more sensitive.

Why Are Advanced HEPA Filters a Cost-Effective Choice?

It is normal to think that high grade filters must be expensive. Yet when you look at the total picture, advanced models often save you money.

Long Service Life With High Dust Holding Capacity

The Customized HEPA Air Filter H13 H14 99.99% V Bank Type Glassfiber Media Replacement Filter has a large surface area thanks to its V Bank shape. This means it can hold more dust before it clogs. As a result, it lasts longer between changes. That alone reduces cost for large facilities that run 24 hours a day.

Energy Efficiency Through Low Resistance Design

The V Bank style also reduces airflow resistance. Fans do not have to push as hard. This saves electricity and reduces wear on the HVAC system. For large buildings like airports, the savings can add up to thousands of dollars every year.

Reduced Maintenance and Replacement Costs

Changing filters takes time and labor. Longer-lasting filters mean fewer service calls. For distributors, this is attractive since clients value lower maintenance. For facility managers, it reduces downtime and keeps systems running smoothly.

Where Can HEPA Filters Be Applied Successfully?

These filters are not just for one or two uses. Their range of applications is wide.

Industrial Cleanrooms and Laboratories

Factories making semiconductors, optics, or biotech goods all depend on particle-free air. If a single particle causes a defect, the whole batch may be lost. Filters are used as a safeguard against this risk.

Food Processing and Healthcare Facilities

Food plants use HEPA filters to meet hygiene rules. Without them, dust or microbes might enter the production line. Hospitals also rely on them for safe patient recovery and infection control.

HVAC Systems and Commercial Buildings

Many office towers, schools, and public spaces use HEPA filters in central HVAC systems. This keeps large groups of people breathing safer air. For example, airports often use high capacity V Bank filters to handle the massive airflow.

Why Choose Healthy Filters as Your Trusted Partner?

It is not only about the filter itself but also about the company behind it. A good partner saves you time, money, and trouble.

Certified Quality and Reliable Manufacturing

Production is carried out in a factory that holds ISO9001 certification. Products are tested in CADR labs and meet CE, ROHS, SGS, FCC, ETL, and UL marks. This means you get filters with documented performance and reliability.

Global Reach With Overseas Warehouse and Fast Delivery

The company ships quickly thanks to its USA warehouse. Delivery within days reduces project delays. For clients in Europe or Asia, logistics partners speed up supply too.

OEM/ODM Services With Professional Customer Support

Every project comes with special needs. OEM and ODM services make it easy to get filters that match your system. Low lead times and helpful support staff make cooperation smoother. Some buyers even mention that they get responses faster than expected, which builds trust.

FAQ

Q1: How often should HEPA filters be replaced?

A: Usage matters. In heavy-use cleanrooms, filters may last one to three years. In homes, eight to twelve months is common.

Q2: Are HEPA filters suitable for food processing plants?

A: Yes. They are used to keep dust and bacteria out of production lines, helping plants meet safety rules.

Q3: Do HEPA filters increase energy costs?

A: Not usually. Modern filters with low resistance designs reduce strain on HVAC systems, and in many cases they lower total energy use.