High-temperature processes in fields like pharmaceuticals, food production, electronics, and metalworking require dependable air filtration to clear away dust, smoke, and other pollutants without any filter breakdown. Ordinary filters tend to break down fast above 150°C, which creates contamination problems, harms equipment, causes unwanted stops, and leads to compliance troubles. You need special high-temperature filters that handle 250°C to 350°C or even more while keeping HEPA-level cleaning power. Picking the correct choice protects process quality, keeps workers safe, and controls costs effectively. For solid, fully customizable high-temperature HEPA options supported by plenty of industry experience, take a look at Healthy Filters, a committed manufacturer that delivers smart solutions and solid chances for distributors.

Core Requirements: Temperature & Equipment Specifics

To prevent failures and achieve optimal performance, filter parameters must be precisely matched to operational conditions. Mismatched parameters may cause premature wear or protective failure under hot conditions.

Maximum Continuous and Peak Temperature Ratings

Filters usually manage steady temperatures of 250°C, 300°C, or 350°C, and some allow brief higher peaks. Always pick ratings that go beyond your process top for extra safety.

Compatibility with Equipment Airflow and Pressure

Match airflow amounts, often 1000 to 3000 m³/h, and starting pressure drops under 240 Pa to fit system fans well. Units that are too big or too tight strain equipment and increase power use.

Thermal Shock Resistance and Ramp-Up Speed

Strong designs handle quick heating without cracking media or seals. This quality fits ovens or tunnels that heat up fast.

Specific Process Needs

Sterilization tunnels demand ultra-pure air, while exhaust systems concentrate on dust capture. Figure out if your job involves intake cleaning or hot gas removal.

Filter Material & Construction

Long-lasting performance in intense heat relies completely on material picks and build strength. Weak parts fail quickly, let particles loose, and threaten safety.

Heat-Resistant Media Choices

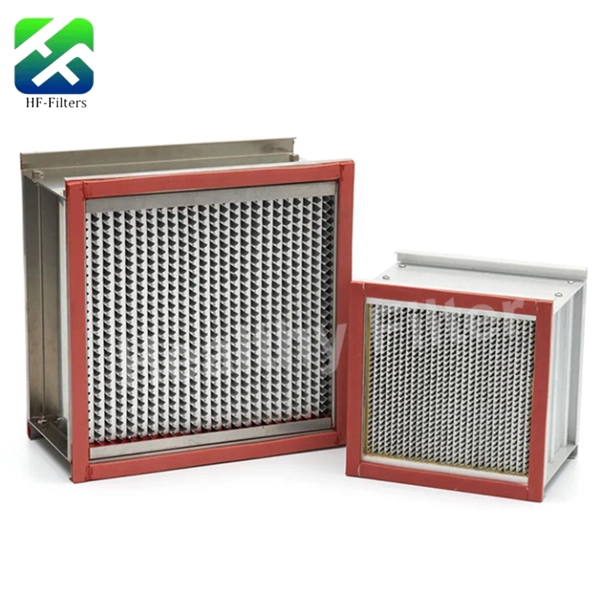

Ultra-fine glass fiber media, frequently borosilicate type, stands up to temperatures reaching 350°C while trapping 99.97% of 0.3-micron particles. This material keeps its shape and cleaning ability during long exposure.

Frame and Separator Durability

Stainless steel frames (SUS304) combined with corrugated aluminum separators offer firm mechanical support and stop media damage. Folded edges on separators give added guard against rips.

High-Temperature Sealants and Gaskets

Special silicone or ceramic glues create airtight joins at 350°C. Choices like PTFE or glass fiber cotton for mounting hold strength through heat cycles.

Pleat Design for Stability and Media Protection

Deep pleats with aluminum foil dividers boost surface area for greater dust storage. This arrangement lowers resistance and lengthens use in tough settings.

The Glassfiber Media High Temperature HEPA Filter performs outstandingly here thanks to its stainless steel frame, aluminum separators, and solid 350°C resistance.

Filtration Efficiency & Performance Metrics

You need steady particle capture even in high heat, balanced with real measures like resistance and capacity. Heat can change media behavior, so checked results count a lot.

HEPA Efficiency Levels at Elevated Temperatures

H13/H14 grades supply 99.97% to 99.999% efficiency at 0.3 microns, checked by sodium flame or scan tests. These grades stay effective under 300°C steady running.

Pressure Drop and Airflow Capacity

Gentle starting drops, around 250-350 Pa, allow high speeds up to 1.5 m/s and flows over 3000 m³/h. This setup cuts power needs on fans.

Dust Holding Capacity and Service Life

The large media surface provides ample dust storage capacity, extending the replacement interval. Its robust structural design minimizes downtime during intermittent operations.

Leak Testing and Certification Standards

Single scan checks at room temperature confirm no leaks, with full match to EN1822. Quality papers come with every shipment for clear records.

Customization & Supplier Reliability

Common sizes often miss the mark for special equipment, so flexibility and trusted partners become vital for unique needs. Good sources supply made-to-order answers without hold-ups.

Custom Sizes and Configurations

Choices go from 305x610x292 mm to bigger panels, with airflow and depth changes. OEM styles fit particular frames or separators.

Testing and Quality Assurance Processes

Conduct rigorous smoke detection and scanning inspections to ensure no leaks before shipment. A complete inspection report shall certify compliance with standards.

Supplier Experience in High-Temp Applications

Deep background in pharma ovens, gas turbines, and metal dust recovery gives useful advice. Solid history lowers chances of problems.

Delivery Speed and Support Services

Quick worldwide shipping and tech help keep jobs on time. Helpful teams manage questions fast.

Cost-Efficiency

To truly save money, don’t just focus on the down payment—consider the total lifecycle costs. In the long run, the benefits of many factors often outweigh the initial investment.

Initial vs. Long-Term Operating Expenses

Better-quality filters cost more at the start but cut replacement needs. Strong materials lower total spending.

Energy Savings from Low Resistance

Soft pressure drops ease fan work, which brings clear power cuts over months.

Reduced Downtime and Maintenance

Longer use and steady results limit stops for swaps. This gain raises output in round-the-clock runs.

Value from Proven Durability

Heat-proof builds stop failures that cause cleanup or fixes. Trusted choices bring good return on money spent.

The High Temperature HEPA Industrial Filter offers great value with choices up to 350°C and strong dust capacity.

Why Choose Healthy Filters for Your High-Temperature Solutions

Healthy Filters is chosen for the high-temperature solution because the company combines specialized expertise with reliable products that meet demanding needs. Their advanced high-temperature product portfolio includes H10 to H14 efficiencies built with durable glass fiber media and stainless steel construction. ISO-certified manufacturing and thorough in-house testing guarantee consistent quality and completely leak-free units every time. Full customization capabilities allow quick adjustments for size, configuration, and specific requirements, while rapid delivery keeps projects on schedule. Global reach supported by a USA warehouse ensures fast access worldwide. A clear focus on ongoing innovation and strong customer partnerships creates lasting value and dependable support for your filtration challenges.

FAQ

Q1: What maximum temperature should you target for high-temperature filters?

A: Select ratings of 250°C to 350°C or higher, depending on continuous or peak process needs, for reliable performance.

Q2: Why choose glass fiber media for high-temperature applications?

A: It resists degradation up to 350°C while maintaining HEPA efficiency and structural integrity.

Q3: How does separator design affect filter durability?

A: Corrugated aluminum separators with hemmed edges protect media and ensure stability under heat and airflow stress.

Q4: What efficiency can you expect at elevated temperatures?

A: H13/H14 levels provide 99.97% to 99.999% capture of 0.3-micron particles, verified through rigorous testing.

Q5: How do high-temperature filters impact overall costs?

A: They reduce long-term expenses through lower energy use, fewer replacements, and minimal downtime.