Products

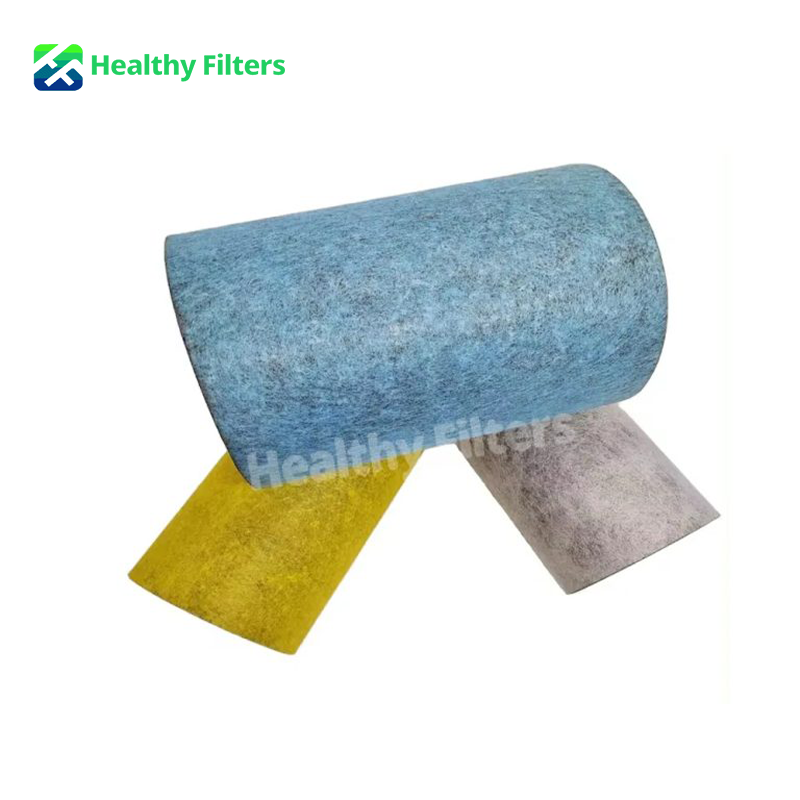

Sandwich Activated Carbon Filter Media Cloth 3 Layers Auto Cabin Air Filter Absorbant Material Paper Roll

Sandwich Activated Carbon Filter Media Cloth 3 Layers Auto Cabin Air Filter Absorbant Material Paper Roll

Features

- Environmental:Carbon fiber filters for air purification and water treatment.

- Chemical:Recovery of organic solvents and compounds.

- Military defense:Gas masks and fire-resistant clothing.

Custom Sizes Are Available Upon Request.

We Offer Extensive Customization Options To Meet Your Specific Needs.

Rigorous Quality Control Procedures

Each Shipment Is Accompanied By A Comprehensive Quality Inspection Certificate, To Ensure They Meet The Release Standard.

Extremely Fast Delivery !

Expedited Processing Available For Urgent Orders, Guaranteeing 1~2 Week Delivery.

Free Samples For Quality Check !

To Facilitate Your Evaluation, We Offer Complimentary A4 Samples. Additionally, We Welcome Factory Tours To Showcase Our Machinery And Production Processes Firsthand.

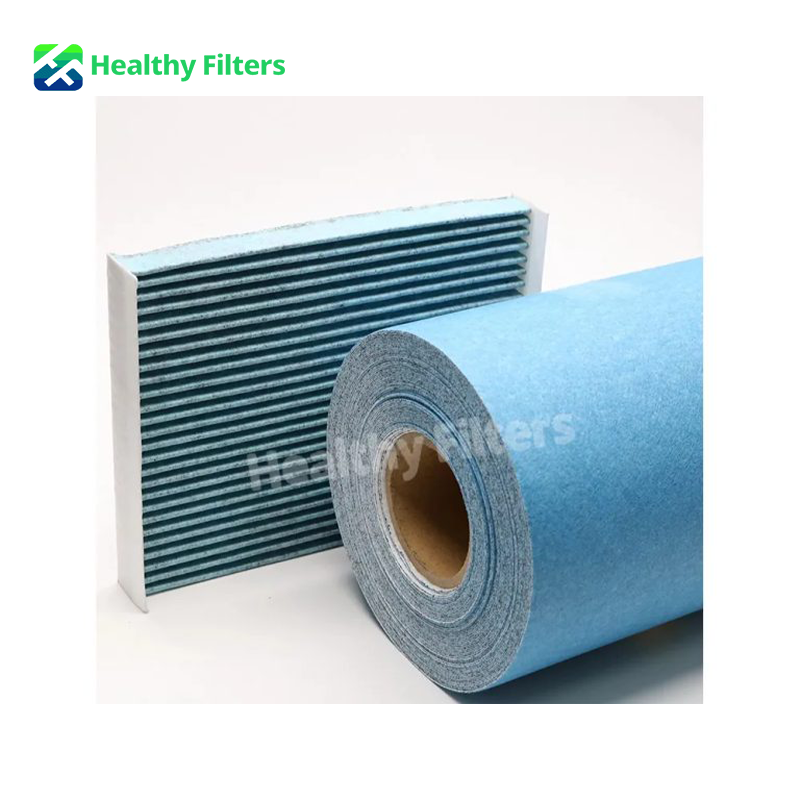

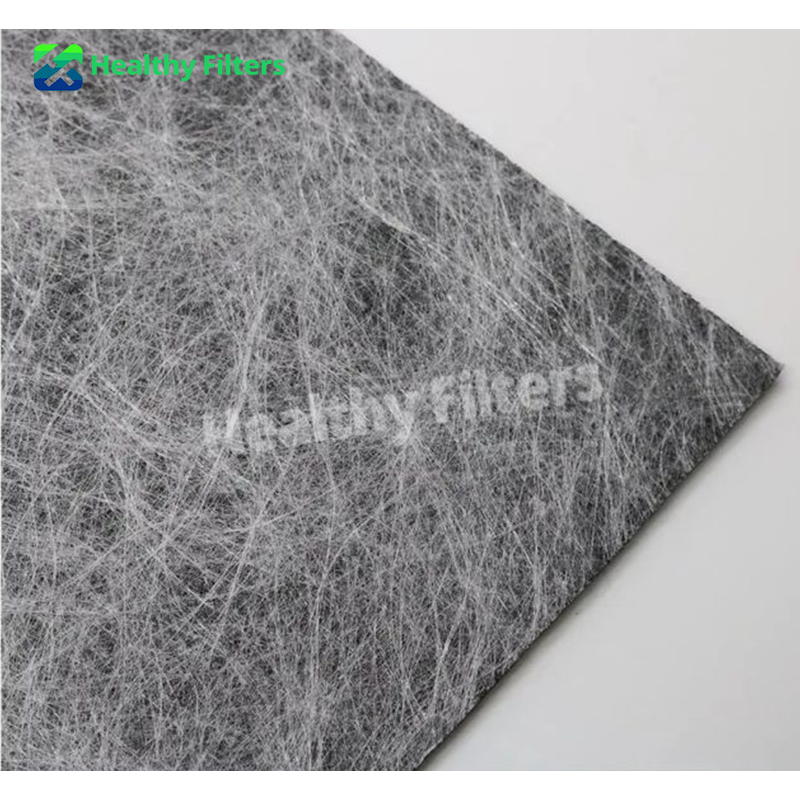

The composite activated carbon cloth is produced using hot pressing technology combined with high-frequency vibration equipment, which evenly spreads coconut shell activated carbon on the surface of a non-woven base material. This creates a high-efficiency filtration material capable of effectively adsorbing various industrial waste gases from the air while maintaining low wind resistance. The material retains the physical properties of cloth, such as strength, flexibility, and durability, while also providing the adsorption features and microporous filter performance of activated carbon.

The material features uniform fiber distribution and equal physical values in all directions. It offers high air permeability to meet sufficient filtering requirements. It is environmentally friendly and provides efficient filtration with good permeability and low resistance.

This fabric is composed of multiple layers of nonwoven materials with varying efficiency rates, with a carbonized middle layer. The nonwoven layers can be chosen from spun-bond nonwovens, spun-lace nonwovens, and needle punch nonwovens.

FEATURES

|

APPLICATIONS

This activated carbon fiber is widely used in central air-conditioning filters, auto cabin air filters, protective clothing, deodorant shoe materials, and other fields. After undergoing a pleating process into finished filter products, it serves as an ideal air filtration media for home and auto air purification. It can also be used for both industrial and domestic water purification. |

SPECIFICATIONS

| Article | Unit | TDS | Test Standard |

| Basis Weight | g/m2 | 520±52 | JB5374-1991 |

| Thickness | mm | 1.75±0.25 | ISO9073-2-1989 |

| Air Permeability | L/m2.s | >1000 | GB/T5453 |

| Filtration Efficiency | % | >65 | TS.8130 (32L/min) |

| Pressure Drop | Pa | <10 |

PRODUCT DETAILS

RELATED PRODUCT

GET A FREE QUOTE

- Kindly send us your project details and floor plan. We will contact you within 24 hours!