CNC machines represent a significant capital investment for any manufacturing facility. Maintaining their precision and operational longevity requires a rigorous approach to environmental control. Airborne particles, ranging from metallic dust to oily aerosols, act as silent destructive agents that compromise internal components. To safeguard your equipment, you can partner with Healthy Filters, an industrial filtration expert providing high-performance solutions that eliminate contaminants, optimize airflow, and significantly reduce equipment downtime through advanced manufacturing excellence.

The Vulnerability of Precision CNC Machinery to Airborne Contaminants

A CNC machine’s inside setup is quite open to the workshop’s outer air. Although CNC machines are mechanically robust, their operational accuracy relies on micron-level tolerances, which are highly susceptible to airborne particulate contamination. Factory air holds a blend of dry bits and coolant vapors that slip into tight covers as time passes.

Invisible Killers of Industrial Performance

Tiny particles in the air often slip past simple screen covers. These pollutants land on light sensors and switch points, which leads to setup mistakes that waste parts and cut output time. As a result, production suffers from these small but steady issues.

Critical Impact on Control Cabinet Electronics

Electronic parts produce heat and need steady cooling. Intake fans draw in dirty air; consequently, dust accumulation on electronic components acts as thermal insulation, hindering heat dissipation and increasing the risk of overheating, premature failure, and erratic program faults. This chain of events shortens the life of key controls.

Friction and Wear from Recirculating Metal Dust

Metal chips and rough dust work like grit when they reach the machine’s moving insides. This material speeds up damage to exact surfaces, and it results in lasting drops in cutting precision. Over time, such wear demands major fixes.

Thermal Stress Due to Clogged Cooling Ports

Blocked air flow stops good heat release inside the machine case. Debris in cooling spots causes heat growth that bends fine parts and cuts motor lifespan. These problems build up and lead to early failures.

How Oil Mist and Dust Accelerate Equipment Depreciation?

Equipment value loss is a sure financial fact, but air factors often push it faster than needed. Oil vapor from cut fluids mixes with dry shop dust to make a tacky layer on all inside areas. This deposit goes beyond dirt; it poses a real risk to the gear’s build strength.

Premature Degradation of Spindle Bearings

Spindles run at fast spin rates, where even small dirt in the oil setup triggers big breakdowns. Fine dust past seal edges makes tiny pits, which cause sounds, shakes, and full lock-ups. Such damage requires quick spindle changes.

Signal Interference in High-Speed Data Circuits

New CNC setups depend on quick data links from the main control to drive parts. Dust that conducts on plugs creates signal mess or direct shorts, so it forces costly swaps of full control units. This issue disrupts smooth runs.

Build-up on Linear Guides and Ball Screws

Straight motion setups need a clean oil coat for even work. Pollutants blend with the oil to create a scrape mix that ruins the smooth face of screws and paths, which calls for regular and pricey rebuilds. Maintenance costs rise from this effect.

Increased Energy Consumption from Cooling Inefficiency

Poor filters make inside fans push harder against dust blockages. This extra work lifts power costs and adds load to the machine’s electric setup. Long-term, it strains the whole system.

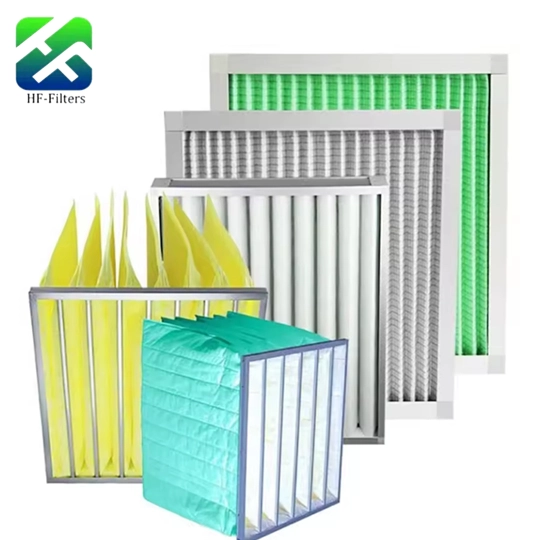

Optimizing Multi-Stage Filtration with Healthy Filters Solutions

Shielding CNC gear needs a step-by-step guard plan for varied particle types and sizes. One filter seldom works in a metal shop’s mixed setup. A multi-step method lets each stage grab set pollutants, so it lengthens both machine and filter life.

Primary Protection with Washable Metal Pre-filters

The front guard should use a tough metal net to catch big chunks and oil bits. These parts stop overload on later filters, and they stay easy to keep up with routine washes. This setup saves on filter swaps.

Secondary Defense via Bag Medium Synthetic Fiber Filters

To grab fine shop dust and smoke, the Bag Medium Synthetic Fiber Filter plays a key role. This level offers deep hold for big air flows without quick blocks. It supports steady operation in heavy use.

Final Polish with Advanced Medium Efficiency Concertina Air Filters

For top air clean near sensitive electronics, the Advanced Medium Efficiency Concertina Air Filter gives wide area in a small form. It catches the tiniest bits before they hit vital paths. This final step boosts overall safety.

Strategic Integration into Industrial HVAC Systems

Shop vent systems must match machine filters well. Adding strong air cleaning to the building’s HVAC cuts base dust levels, which makes on-machine filters work much better. This combined approach cuts risks across the site.

Maximizing Durability with Bag Medium Synthetic Fiber Filters

Picking a second-stage filter for factory work means focusing on dust hold and build strength. Basic filters often give out under strong fan push or in wet air. The fiber pocket style fixes this by offering a firm and big-hold base.

High Dust Holding Capacity for Industrial Loads

Pocket shapes give a much bigger clean area than flat sheets. This lets the filter hold lots of metal dust while keeping air flow steady for longer. It cuts down on change-outs in busy shops.

Durable Synthetic Fibers Resistant to Humidity

Factories face changing wet levels from coolant work. Synthetic fibers skip water soak or germ build, so the filter stays solid and clean during full use. This trait aids long runs without issues.

F6 to F8 Efficiency Options for Fine Particles

These filters come in varied clean rates for your shop’s needs. For common dust or small grind bits, you pick the right guard level. This choice fits exact demands.

Low Pressure Drop to Reduce Fan Energy Costs

Even with strong clean power, these pocket filters keep air block low. This stops vent motors from getting too hot and holds power use steady as dust builds. Energy savings follow naturally.

Enhancing Airflow with Advanced Concertina Air Filters

For areas where space is limited but high efficiency is required, concertina or V-bank filters provide a sophisticated solution. These filters are particularly effective for protecting the intake ports of control cabinets where airflow must be maximized to prevent heat spikes in the delicate electronic components.

V-Bank Geometry for Superior Surface Area

The folded geometry of these filters provides an exceptionally large filtration area within a standard frame size. This translates to a slower face velocity of the air, which allows for more effective particle capture and longer service intervals.

Robust Construction for Constant Airflow Environments

Industrial fans often run twenty-four hours a day, putting constant mechanical stress on filter media. These filters feature reinforced frames and stable pleat spacing that prevent bypass and withstand continuous pressure.

Minimized Resistance for Optimal Motor Cooling

By reducing the effort required to pull air through the filter, these units help maintain a stable internal temperature for your CNC motors. This cooling efficiency is a direct contributor to the long-term reliability of the drive systems.

Versatile Applications in Commercial and Industrial Spaces

While perfect for CNC protection, these filters are also suitable for office areas and cleanrooms within the factory. Their versatility allows you to standardize your filtration inventory across the entire facility.

Why Healthy Filters is the Premier Partner for Machinery Plants?

Choosing a filter provider is as critical as the components themselves. You need a partner that blends technical innovation with a firm commitment to quality. A reliable supplier supports your maintenance strategy with high-performance products specifically engineered for the rigors of modern manufacturing.

With decades of expertise in industrial filter manufacturing, the team develops solutions that address real-world shop challenges, ensuring every product can handle the demands of metalworking and machining environments. This skill is further reflected in their tailored OEM solutions, providing custom fits for non-standard CNC units to ensure all equipment remains shielded. Furthermore, strict ISO quality control and material certifications guarantee that each filter performs as specified. To minimize costly downtime, a global distributor network ensures rapid maintenance support and fast delivery. This comprehensive approach to quality and accessibility makes them the premier partner for machinery plants worldwide.

FAQ

Q1: How often should I replace the bag filters on my CNC machine?

A: You should typically replace them every 3 to 6 months depending on your production volume and the amount of dust generated. Checking the pressure drop across the filter is the best way to determine the exact timing.

Q2: Can I wash and reuse synthetic fiber bag filters?

A: No, synthetic fiber bag filters are disposable to ensure maximum efficiency. Attempting to wash them can damage the micro-fibers and significantly reduce their ability to trap fine particles.

Q3: Will using a higher efficiency filter damage my machine’s cooling fan?

A: Not if you choose a high-quality filter with low initial resistance. Products like concertina filters are designed to provide high efficiency without placing excessive strain on the cooling motors.

Q4: Do these filters help with oil mist as well as dry dust?

A: While they can capture some mist, it is best to use a metal mesh pre-filter to handle heavy oil droplets first. This prevents the synthetic filters from becoming saturated with oil too quickly.

Q5: Are custom sizes available for older CNC models?

A: Yes, custom OEM solutions are available to provide a perfect fit for any machine model, ensuring that older equipment can benefit from modern filtration technology.