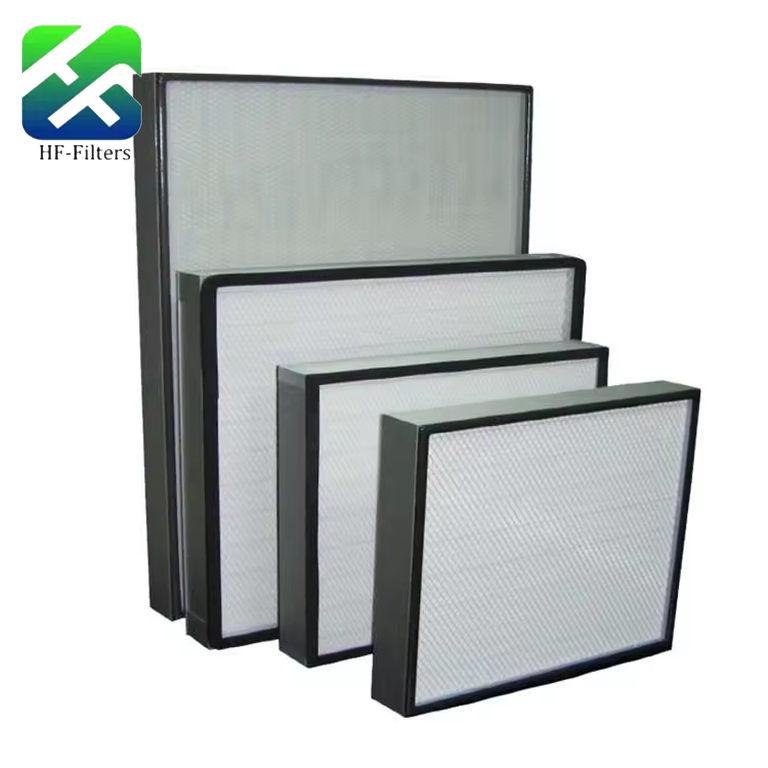

HEPA filters are a common type of filtration equipment. They use ultra-fine glass fiber paper as the filter material, offering strong filtration performance. They are widely applied in clean and purified environments across multiple industries such as pharmaceutical and biotechnology, precision instruments, beverages, and food. Let’s explore the functions and usage precautions of HEPA filters.

Functions of HEPA Filters

Adopt multi-stage combined filtration to meet the needs of various users. Features a quick-change filter design for easy use and maintenance.

The filter material contains no PVC or dyes, making it environmentally friendly and suitable for food-grade filtration.

Offers high air flow rate, low pressure drop, high filtration efficiency, and reliable operation.

The filter material uses an adhesive design that traps dust particles effectively, enhancing filtration results and preventing secondary pollution. Its internal structure is designed to be denser toward the direction of purified air flow, extending the equipment’s service life. Additionally, to prevent accidental breakage, the filter material is a high-performance non-woven fabric made of break-resistant synthetic fibers, reducing the risk of leakage.

Usage Precautions for HEPA Filters

Never exceed the filter’s maximum pressure rating. This ensures the effective use of the HEPA filter and guarantees safety during operation. The pressure resistance of the filter’s accessories is particularly important and must be taken seriously.

Before installing the HEPA filter, thoroughly clean the cleanroom. Use a vacuum cleaner equipped with an ultra-clean filter bag for dust removal. If installed in a ceiling plenum, the plenum must also be fully cleaned.

After meeting hygiene requirements, conduct a trial operation of the purified air conditioning system for more than 12 hours. Repeat the cleaning process before installing the HEPA filter.

Transport and store the HEPA filter in accordance with the manufacturer’s requirements. Handle it gently during transportation to avoid affecting equipment performance.

Before installation, inspect the equipment, including checking if parts and dimensions meet requirements, verifying the product certificate of conformity, and confirming that technical performance aligns with design specifications.

When sealing the gap between the HEPA filter and the frame, ensure the filler surface, filter frame surface, and liquid tank are clean.

In summary, HEPA filters deliver excellent filtration performance and are used in clean factories across various industries. We hope the above information provides useful assistance. If you need to learn more about HEPA filters or other related information, please follow our homepage for timely updates.