The history of air filtration shows an ongoing search for cleaner air, shifting from simple mechanical barriers to exact control at the molecular scale. As environmental issues change from factory smoke to tiny viral dangers, the technology has to keep up. You probably want a partner that mixes this past knowledge with fresh ideas. Healthy Filters, started in 2016 and based in Shenzhen, serves as a leading producer in this area. This skilled group offers various affordable options, from HEPA and activated carbon to custom non-woven fabrics. With an ISO9001 approved factory, a 30 cubic meter CADR testing center, and a key USA warehouse in Nashua, they deliver quickly and handle professional OEM needs well. Their goal of “Clean Air, Healthy Life” comes with worldwide approvals like CE, ROHS, and UL, so they make a solid pick for your upcoming filtration work.

19th Century: Industrialization and the Early Necessity of Protection

The quick growth of coal-fueled factories in the 19th century caused the first big air quality problem in modern times. Early inventors aimed to shield people from thick smoke and harmful chemical fumes. This period started the use of natural substances to catch pollutants before they could harm the lungs.

Coal Smoke Hazards and the First Charcoal Masks

Early factory filters relied on charcoal to soak up dangerous gases. These basic tools laid the groundwork for today’s chemical filtration, since they proved that porous carbon could grab molecules that regular screens could not touch.

Basic Mechanical Separation and Fiber Screening

Filtration kicked off with plain screens meant to stop big pieces of debris. These initial efforts set the basic rules for airflow resistance and particle trapping, which still guide the field now.

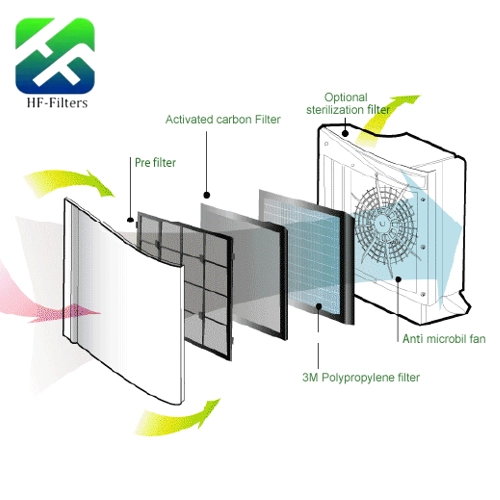

Strategic Focus: Activated Carbon Media

Today’s activated carbon media builds on this tradition. These items use particles with lots of surface area to clear out smells, benzene, and radon, significantly reducing odors and VOC concentrations such as benzene and formaldehyde.

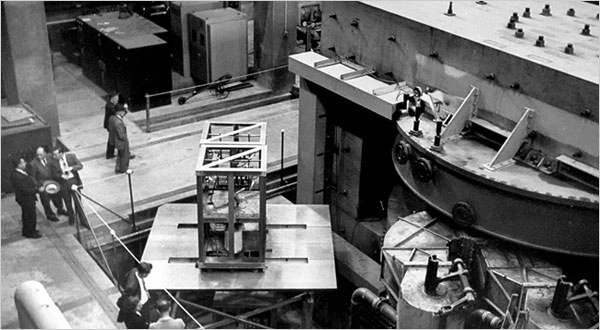

1940s: The Atomic Age and the High-Efficiency Breakthrough

The 1940s turned filtration from a nice extra into a must-have for staying alive. In the Manhattan Project, workers needed ways to hold back radioactive tiny particles. This urgent setting sparked the HEPA standard, which stands as the top mark for air cleanliness around the world.

Manhattan Project Requirements and Radioactive Particle Control

The push for total lockdown pushed experts to create thick, layered fiber setups. This method made sure that even the smallest radioactive bits stayed caught in the filter material.

Defining the 99.97% True HEPA Performance Standard

World standards set True HEPA as a filter that grabs 99.97% of particles down to 0.3 microns. This clear efficiency point means air coming out holds almost no tiny pollutants.

Strategic Focus: Precision-engineered H13 & H14 HEPA Filters

Now, H13 and H14 filters draw on PP or glass fiber to hit these tough rules. They let air flow while holding back fine particles, giving key safety in medical spots and labs.

1960s-1980s: The Cleanroom Era and Micro-Manufacturing Boom

As the chip and drug sectors expanded, the call for super-clean spaces grew strong. Filtration moved from broad safety to backing advanced making processes, where one bit of dust could spoil a microchip.

Supporting Semiconductors and Pharmaceuticals with ULPA Technology

The rise of Ultra-Low Penetration Air (ULPA) filters let plants achieve 99.999% efficiency. This sharp control supported the large-scale output of electronics and drugs that people rely on daily.

Transitioning from Specialized Military Use to Commercial HVAC

Tech first built for shelters and labs spread to office setups and hospitals. This shift brought high-efficiency air quality to everyday folks via main ventilation setups.

Strategic Focus: Mini-Pleat and V-Bank Filters

Current factory options use mini-pleat and V-bank styles to boost the filtration area. These setups cut down on airflow pushback and lengthen the life of gear in tough cleanroom conditions.

1990s-2010s: Urbanization and the Rise of Residential Air Quality

In the late 20th century, attention turned to air quality at home. City growth raised PM2.5 amounts and worries about inside pollution from building stuff. Filtration turned into a regular part of home devices to keep living areas safe.

Combating PM2.5 Smog and Indoor Formaldehyde Pollution

Formaldehyde from furniture and paints emerged as a main inside health risk. Better filters now mix trapping with chemical bits to break down these bad VOCs.

The Proliferation of HEPA in Vacuums and Household Appliances

Vacuum cleaners and air purifiers, as well as some air cleaning systems, are beginning to adopt HEPA filtration technology to prevent the redistribution of fine particles. This setup makes sure that cleaning one spot does not dirty the air elsewhere in the house.

Strategic Focus: Formaldehyde Removal and Vacuum HEPA Replacements

Fresh replacement filters apply a new method with super-soaking particles. These parts wipe out formaldehyde, benzene, and other gases from decor materials at high rates.

2020s: The Global Pandemic and the Shift to Pathogen Defense

The latest worldwide health event changed the field’s aim from just catching particles to fighting germs directly. Now, filters must not only hold viruses but also cut their living power to stop further spread.

Moving Beyond Particle Trapping to Active Viral Neutralization

Current filter materials add special coatings to wipe out bacteria and viruses right away. This forward step layers extra guard on top of usual mechanical work.

Utilizing Nano-Silver Materials for Long-term Microbial Inhibition

Nano-silver works as a strong germ fighter. When added to non-woven fabrics, it gives lasting shield against many bacteria like Staphylococcus aureus and E. coli.

Strategic Focus: Nano-Silver Antibacterial Fabric

Lab checks reveal that nano-silver non-woven fabric cuts H5N1 avian influenza virus power by 2.75 log. So, the virus strength falls to 1/500th of what it was, which greatly drops infection odds.

The Next Decade: Sustainability and Hybrid “Smart” Filtration

Ahead, the filtration world heads toward green practices and smart operation. You will most likely choose options that give lasting worth via reusable stuff and good energy use.

Transitioning to Fully Recyclable and Washable Filter Media

Green standards now rank high for sellers and partners worldwide. Full polyester fiber setups make filters that last, resist acids, and handle washing.

Combining AI-driven Air Sensors with Multi-functional Composite Layers

Coming systems will draw on live info to tweak airflow and filtration strength. Layered filters will blend several types into one piece to deal with dust, chemicals, and germs all at once.

Strategic Focus: 3D Mesh Washable Filters and Sustainable PET Media

3D mesh filters from 100% polyester offer strong moisture addition and full washability. These repeat-use parts cut down trash and last up to 12 months, based on the setting.

Why Healthy Filters is the Premier Strategic Partner for the Future

- Global Certification Compliance: You get items that follow ISO9001, CE, ROHS, and UL rules, so quality and safety hold up in all global spots.

- Advanced R&D Facilities: The 30 cubic meter CADR testing center and set clean rooms enable strict checks and steady product upgrades.

- Strategic USA Warehouse: Quick shipping and local help come from the Nashua, USA site, skipping time zone issues for North American users.

- Professional OEM Flexibility: You can get custom designs with short waits, fitting any size from single jobs to big market needs.

- Proven International Reputation: A solid history in North America, Europe, and Southeast Asia shows steady focus on top filtration and happy customers.

Healthy Filters stands ready to help you meet tomorrow’s air quality challenges with proven technology, sustainable innovation, and reliable global supply.

FAQ

Q1: What is the difference between H13 and True HEPA filters?

A: True HEPA means filters hitting 99.97% efficiency at 0.3 microns, which usually matches the H13 grade in the EN1822 standard.

Q2: Can HEPA filters be washed and reused?

A: Most glass fiber or PP HEPA filters cannot take washing, but special PET or PTFE media and 3D mesh filters work for multiple washes and reuse.

Q3: How often should I replace an industrial air filter?

A: Swap cycles often run 6 to 12 months, but this depends on the exact surroundings and pollutant amount.

Q4: Do these filters help with formaldehyde from new furniture?

A: Yes, filters with treated activated carbon or removal particles can clear over 95% of inside formaldehyde and VOCs.