The European air filtration sector grows quickly because of strict environmental rules and rising focus on indoor air purity. Entering this area calls for a mix of practical skills, rule following, and solid product supply. To handle this busy field, a supplier with a strong history proves essential. Healthy Filters, started in 2016, stands as a top maker of modern air cleaning options. An ISO9001 approved plant and a 30 cubic meter CADR test lab enable customized filtration solutions that gain CE, ROHS, and UL certifications. Knowledge covers HEPA filters to custom non-woven cloths, so each item hits top output. For steady OEM work or a smart distributor partnership, the drive for “Clean Air, Healthy Life” makes this firm a strong match for a European startup.

Step 1: Conduct Thorough Market Research on European Standards

Starting a venture in Europe demands a close look at the tech rules shaping the field. The European Union sets some of the toughest air quality benchmarks worldwide, and failing them can lead to major legal and money hurdles.

Compliance With EN779 and EN1822 Regulations

Standards such as EN779 for rough and medium filters plus EN1822 for HEPA and ULPA types set the output levels needed for different uses. Stock must match these exact groups to meet local build rules and factory insurance needs.

Identification of High Demand Industrial Sectors

Filtration needs differ a lot by European zones. Northern areas stress power-saving HVAC setups for home heating, while Central spots show huge calls for premium factory filters in car making and drug production.

Analysis of Competitive Landscape in EU Member States

Reviewing current local firms helps spot open spots in the field. Many buyers in Europe want a mix of the steep price of home brands and the strong results from focused global makers who give easy delivery times.

Step 2: Select a High Quality Product Portfolio for Local Needs

Picking products forms the base of the business plan. A lineup should cover basic air flow wants and special high-output demands to grab more market room.

Integration of Universal Replacement Media Air Filters for Versatility

Supplying Universal Replacement Media Air Filters serves users with varied gear. These come in levels from H11 to U17 using PP, glass fiber, or PTFE stuff, so choices include cleanable types or max output for tiny dust catch.

Deployment of Synthetic Fiber Pocket Filters in HVAC Systems

HVAC units in European office builds depend much on pocket filters. Synthetic fiber ones with aluminum edges work well since they hold lots of dust on a big area yet keep air flow easy, key for hitting energy goals in Europe.

Implementation of High Quality HEPA Filters for Clean Room Standards

For key fields like chip tech or medical centers, High Quality HEPA Filters become a must. They use very fine glass fiber or blown melt stuff to reach 99.97% to 99.9999% output, so even small particles get caught well in set spaces.

Step 3: Establish a Reliable Supply Chain and Manufacturing Base

A tough supply line makes sure orders fill on time. In Europe, where quick delivery counts, the skill to get or make goods close by sets lasting success.

Procurement of Advanced Air Filter Making Machines for Local Production

Planning to build in Europe cuts ship fees and taxes, so buying Air Filter Making Machines makes sense. Auto lines for folding, sticking, and edge building give steady quality checks and fast growth in making.

Optimization of Logistics and Warehousing Across European Borders

Smooth goods movement over lines matters a lot. A main storage spot handles stock for many EU lands, so it skips single border waits and speeds up sends to area buyers.

Evaluation of Raw Material Sustainability and Quality Control

Buyers in Europe value green choices. Raw stuff like full polyester fibers or active carbon should fit RoHS and REACH rules. Steady checks for CADR and germ-fighting traits make sure the end item hits stated specs.

Step 4: Build a Robust Distribution and Partner Network

The expansion of European market often needs multi-party cooperation. A group of partners with area know-how and setup skills speeds up entry into the market.

Recruitment of Experienced Regional Sub-Distributors

Area sub-sellers often link with site heads and factory spots. Teaming with them uses their close ties, while focus stays on big buys and brand care.

Collaboration With Professional HVAC Installation Contractors

Filters serve as replaceable parts in big units. Links with HVAC fitters mean products get suggested in regular checks and fresh builds, building ongoing income flow.

Utilization of Healthy Filters Global Distributor Support Program

Linking with a set maker opens marketing tools, tech sheets, and good prices. This aid proves key in bids for big European jobs, where papers match the item in weight.

Step 5: Implement Targeted Digital Marketing Strategies

Online setup works as the front door in B2B sales. European shoppers search the web a lot before reaching out, so strong web sight drives main leads.

Optimization of B2B Lead Generation Through Technical Content

White papers on filter output and savings cases draw European tech experts. Content breaking down stuff like PTFE versus glass fiber builds trust and standing with the crowd.

Participation in Leading European Environmental Trade Fairs

Shows like Filtech or HVAC events in Germany and France aid networking. They let product quality show live and meet possible team members in person, a core part of European deals.

Enhancement of Brand Trust via International Certifications

Showing ISO9001, CE, and SGS marks on sites gives the proof European buyers need. These signs confirm processes and safety hit world levels.

Why Partner With Healthy Filters for Your European Venture?

Picking the best supplier shapes the new venture most. Healthy Filters gives a full setup built for world growth and tech strength.

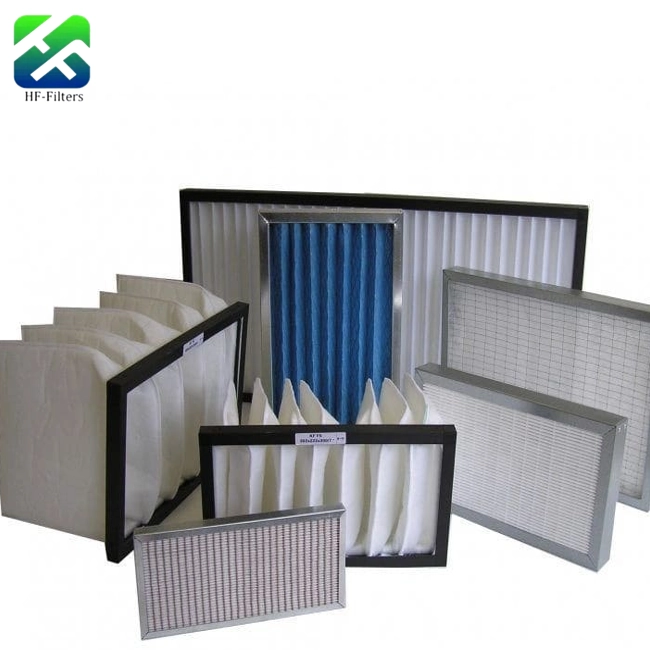

Diverse Range of High Efficiency Filtration Solutions

From simple G3 pre-filters to U17 super-high output ones, the lineup fits all European uses. Clients wanting wet filters from 3D net or germ-killing nano-silver treated stuff find options, so no lead gets lost.

Decades of Expertise in Air Filter Manufacturing Technology

The firm’s tech base allows much OEM bend. With modern gear and a set clean room, the plant makes filters that hold shape and work in hard factory spots.

Comprehensive Support System for Global Business Partners

More than items, the team brings calm. Set logistics and lean making give cheap fixes that keep good edges in the strict European field.

FAQ

Q1: What are the main filter efficiency standards used in Europe?

A: Europe mainly uses the EN779:2012 standard for general ventilation and the EN1822:2009 standard for high-efficiency HEPA and ULPA filters, though ISO 16890 now sees wide use too.

Q2: Can I wash and reuse air filters in European HVAC systems?

A: Some stuff like synthetic fiber and PET allows washing, but high-efficiency HEPA filters from glass fiber usually cannot since water harms the fine fibers.

Q3: Is it better to import finished filters or manufacture them locally in Europe?

A: Bringing in ready goods speeds market start, but putting money in filter making machinery for close building cuts long-run ship costs and boosts send speeds.

Q4: What certifications do European B2B buyers look for in air filters?

A: Buyers often seek CE marking for safety, RoHS for harmful stuff limits, and output certs from labs like SGS or Eurovent.