A single contamination event can cost a semiconductor fab millions. A poorly designed HVAC filter can waste thousands of dollars in electricity every year. The difference between disaster and reliable performance always comes down to one component: the pleated filter. When lives, yields, and budgets are on the line, engineers worldwide trust the same manufacturer. Healthy Filters, founded in 2016 in Shenzhen, produces every gram of melt-blown media and every pleat in its own ISO 9001 cleanroom. With a 30 m³ CADR lab, full EN 1822 scanning stations, and a USA warehouse, stock ships in 7 days and custom orders in 12–18 days globally.

How Pleated Filters Actually Work?

Pleated filters dominate modern air filtration because they pack massive surface area into compact frames.

Massive Surface Area Advantage

Mini-pleat technology folds the media like an accordion, fitting up to 30 m² of material into a standard 610 × 610 mm frame. This dramatically increases dust holding capacity and extends service life compared to flat panels.

Progressive Density Structure

The media starts loose on the air-entering side to capture large particles quickly. It then gradually tightens toward the clean side so fine particles penetrate deeper and avoid surface blinding.

Hot-Melt Separator Benefits

Precise thermoplastic beads replace old-fashioned aluminum separators, eliminating metal particle generation and corrosion in humid environments. They also allow tighter pleat spacing and higher media area without collapse.

Lower Pressure Drop Reality

Large surface area and even airflow distribution keep resistance 40–60 % lower than bags or flat filters across the entire life cycle. Fans consume less electricity and run cooler for years.

Superior Dust Holding Capacity

Progressive structure stores several kilograms of dust per square meter before final resistance is reached. Change-out intervals double or triple, reducing labor and waste disposal costs.

Cleanroom & Semiconductor: When 99.999 % Is Non-Negotiable

One 0.1 µm particle can destroy an entire wafer batch worth millions.

H14 vs U15 Difference

H14 guarantees ≥99.995 % efficiency at MPPS and is sufficient for most ISO 5–6 zones. U15 pushes efficiency beyond 99.9995 % and becomes mandatory for EU Grade A and sub-10 nm nodes.

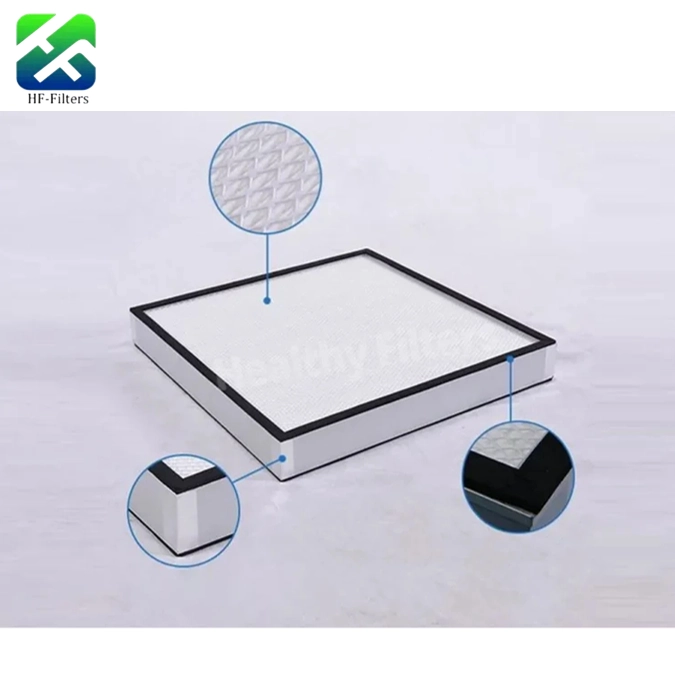

Mini-Pleat Gel-Seal Design

Hot-melt separators combined with a liquid gel channel create a permanent, vibration-proof seal inside FFU housings. Zero bypass is maintained even after years of continuous operation.

100 % Scan-Tested HEPA

Every single filter is individually leak-tested with PAO aerosol according to EN 1822 before it leaves the factory. The Custom Industrial HEPA H14 Pleated Air Filter ships with a serialized scan report you can show any auditor.

Commercial HVAC & Offices: Balancing Cost and Performance

Electricity is the largest lifetime expense of any air handling unit.

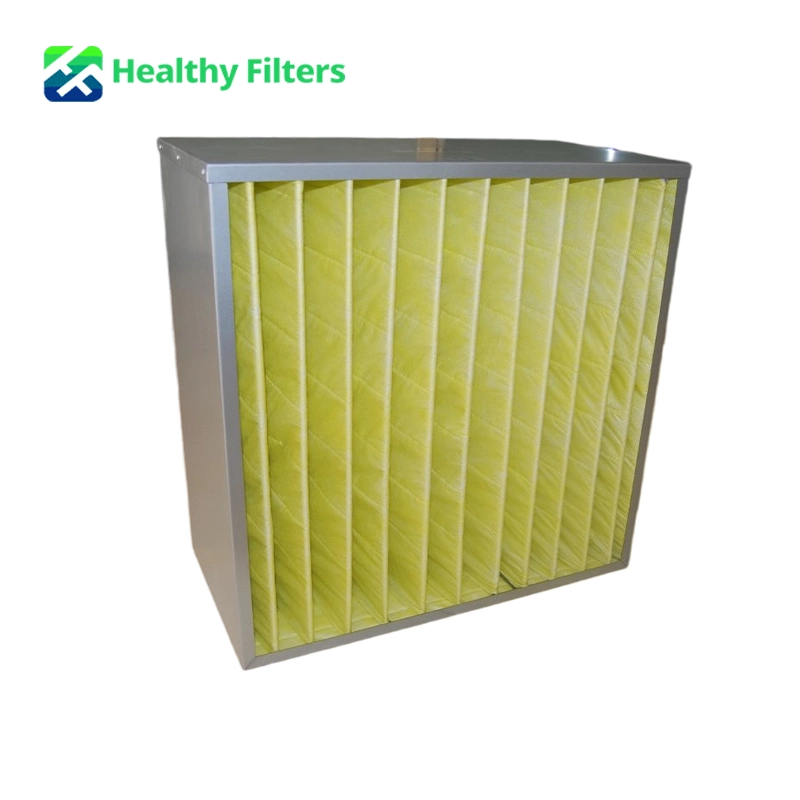

F7–F9 Box Superiority

Rigid V-bank construction prevents pleat collapse at high velocity, unlike soft pocket bags that sag and block airflow. This maintains consistent performance for the entire service life.

18–24 Months Service Life

Up to 28 m² of progressive synthetic media per box keeps final resistance under 350 Pa in normal office dust loads. Most buildings only need to change filters once every one to two years.

Ultra-Low Energy Consumption

The Medium Efficiency Box Air Filter for Commercial HVAC Systems starts below 120 Pa initial resistance and saves 15–30 % fan power compared to low-quality alternatives.

Hospitals & Pharmaceuticals: Zero Leakage Required

Regulatory auditors and patients demand absolute certainty.

Gel-Seal vs Knife-Edge

Gel-seal tolerates repeated removal for integrity testing without losing sealing integrity. Knife-edge works well only when housing machining is perfect; gel-seal forgives small tolerances.

Individual PAO Scan Reports

100 % of filters are scanned with PAO aerosol and shipped with a certificate showing no leak larger than 0.01 %. Auditors accept the report immediately.

GMP-Ready Traceability

Every raw material batch, pleating run, and final test is recorded and linked to the filter serial number. Full documentation is supplied automatically with every order.

Painting Booths & Heavy Dust: Extreme Loading Survival

Paint overspray and welding fume create some of the harshest conditions on earth.

600G Ceiling Cotton Role

High-loft synthetic progressive media captures overspray on the surface while letting air pass freely. It holds kilograms of sticky paint without increasing pressure drop rapidly.

PS-100 Fiberglass Floor

Thick fiberglass paint arrestor pads trap heavy droplets and prevent them from reaching exhaust fans. They stay flame-retardant to DIN 53438 F1 even when saturated.

Flame-Retardant F1 Standard

The media neither melts nor drips when exposed to direct flame, meeting the strictest automotive and aerospace fire codes.

Home & Portable Purifiers: Real H13 in Small Size

Consumers refuse loud machines and filters that last only three months.

Composite HEPA+Carbon Layer

True H13 pleated media is combined with activated carbon in one cartridge to remove both particles and odors simultaneously. No need for separate stages.

8–12 Months Lifespan

Large media area and progressive density deliver real-world durability in polluted city apartments. Most users only replace once per year.

Quiet Low-Resistance Design

Hot-melt spacing and optimized pleat geometry keep noise below 35 dB while still achieving 400–600 m³/h CADR.

Why Healthy Filters Keeps Winning Every Comparison?

Paper specifications are cheap, while consistent real-world results are priceless. Ready to stop gambling with filtration performance? Contact Healthy Filters today for high-quality pleated filters.

- In-House Media Production: Every roll of melt-blown is manufactured and tested on-site, guaranteeing identical fiber diameter and gram weight every meter.

- EN 1822 Full Scanning: 100 % of finished filters are individually leak-tested, not just random batch sampling.

- ISO 9001 Cleanroom Standard: All pleating and framing happens in controlled environment to prevent contamination before the filter reaches you.

- 7–15 Day Custom Delivery: Most custom sizes ship faster than competitors’ stock items, including full test reports.

- USA Warehouse Stock: Popular sizes arrive in North America within one week, eliminating months of ocean-freight waiting.

FAQ

Q1: How long do H14 pleated filters last in real cleanrooms?

A: With proper pre-filtration in ISO 7–8 rooms, 18–36 months is typical before final pressure reaches 500 Pa or scan testing shows leakage.

Q2: Do pleated box filters actually save energy in office buildings?

A: Yes. F7–F9 pleated boxes reduce average pressure drop 40–60 %, cutting fan electricity consumption 15–30 % over the filter life.

Q3: Is gel-seal worth the higher price in pharmaceutical plants?

A: Absolutely. It eliminates bypass risk during filter changes and survives repeated removal for annual integrity tests without damage.

Q4: Can pleated filters handle heavy paint overspray safely?

A: Yes. 600G synthetic ceiling cotton plus PS-100 fiberglass floors achieve >98 % arrestance and meet DIN 53438 F1 flame-retardant standard.