Picking the right air filter material isn’t just about meeting rules. It’s about getting clean air without choking your system or jacking up costs. Whether it’s a big office, a sterile cleanroom, or a busy factory, the filter media you choose changes how well your air stays clean and how hard your equipment has to work. Healthy Filters, a pro manufacturer from China, gets this. They make filter materials like synthetic bags, activated carbon, and fiberglass paper that hit the sweet spot of performance and practicality. Their stuff is built for real-world needs, from HVAC setups to high-stakes industrial environments.

How Do Synthetic Bag Filter Materials Perform in Balancing Efficiency and Airflow?

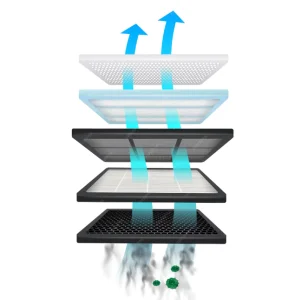

Synthetic bag filter materials are engineered to strike a precise balance between particle capture efficiency and maintaining adequate airflow. These filters are often used as pre-filters or secondary filters in HVAC systems where both dust load capacity and low pressure drop are critical.

Synthetic bag filter materials for commercial HVAC systems

For commercial settings such as office buildings or retail spaces where consistent airflow is essential but particulate control must not be overlooked, these filters offer an excellent middle ground. You can explore options like Healthy Filters’ Synthetic Bag Filter Material for durable performance across varied environments.

Multi-grade filtration performance with M5 to F9 options

A major advantage of synthetic bag filters is their availability in multiple grades—from M5 to F9—allowing you to match the filtration level to your specific needs. Explore our range of Healthy Filters synthetic bag filter materials, available in M5, M6, F7, F8, and F9 ratings. These ratings correspond to increasing levels of particulate removal efficiency without significantly compromising airflow.

High dust holding capacity and low initial resistance

The design of synthetic media supports deep particle penetration, which translates into higher dust holding capacity. This means fewer replacements over time and lower maintenance costs. These materials are designed for efficient air filtration, offering high-performance solutions for various filtration requirements. Additionally, their low initial resistance helps maintain system energy efficiency—a key factor in large-scale HVAC operations.

Why Consider Activated Carbon Filter Materials for Filtration Needs?

While particulate filters handle solid contaminants effectively, they fall short when it comes to odors or chemical pollutants. That’s where activated carbon media steps in—offering gas-phase filtration capabilities that go beyond what traditional filters can achieve.

Effective adsorption of odors, gases, and VOCs

Activated carbon works through adsorption—a process where molecules adhere to the surface of the carbon granules or fibers. These materials effectively capture and neutralize odors, pollutants, and harmful gases, ensuring a cleaner and healthier indoor environment. This makes them ideal for applications involving volatile organic compounds (VOCs), smoke, or chemical fumes.

Consistent airflow with chemical filtration capabilities

Despite its specialized function, activated carbon media maintains moderate airflow resistance. The material is typically integrated into roll formats or pleated designs that allow air to pass through while interacting with maximum surface area. This ensures that even while removing gaseous contaminants efficiently, the system doesn’t suffer from excessive pressure drop.

Activated carbon rolls offer versatile applications in air purification

From cleanrooms to kitchens to industrial zones processing chemicals or solvents—the versatility is unmatched. Activated Carbon Filter Material options include rolls and customizable panels that can be adapted based on application demands. Choose Healthy Filters for high-quality activated carbon filter materials that provide reliable performance and improved air quality.

What Are the Strengths of Fiberglass Air Filter Paper in Air Handling Systems?

When ultra-fine particle capture is required—especially at HEPA levels—fiberglass filter paper becomes indispensable. It’s commonly used in environments where even microscopic particles pose significant risks.

Superior particulate capture due to dense microstructure

Fiberglass media consists of randomly arranged glass fibers forming a dense matrix capable of trapping particles as small as 0.3 microns with high efficiency. This high-quality material effectively captures particles and contaminants, ensuring cleaner and healthier indoor air.

Stable performance under high temperature and humidity conditions

Unlike some synthetic alternatives that degrade under heat or moisture exposure, fiberglass maintains structural integrity across extreme conditions. That makes it suitable for pharmaceutical labs or electronics manufacturing facilities requiring stable environmental control.

Healthy Filters’ fiberglass media ensures high-efficiency HEPA-level filtration

Options like the Fiberglass Air Filter Paper deliver H13-H14 grade HEPA performance using glass fiber media.Our HEPA Panel Filter uses high-quality Glass Fiber Media to capture particulate matter efficiently.

How Does Each Material Type Compare in Terms of Pressure Drop?

Pressure drop directly affects energy consumption in any air handling system. Choosing the right material involves evaluating how much resistance each type introduces while maintaining performance.

Synthetic bag filter media offers balanced pressure drop across grades

These filters are known for their low initial resistance even at higher efficiency levels like F8 or F9. That makes them suitable where airflow consistency matters just as much as cleanliness.

Activated carbon media maintains moderate resistance while adsorbing gases

Though slightly more restrictive than purely mechanical filters due to its adsorption layer thickness, it still allows sufficient throughput without severely burdening fan systems.

Fiberglass filter paper presents higher resistance but excels in fine particle retention

Its dense structure leads to higher pressure drops compared with other types—but that’s often acceptable given its role in final-stage filtration scenarios like cleanrooms or surgical suites.

Which Filter Material Provides the Longest Service Life?

Service life isn’t just about durability; it’s about how long a material can function before needing replacement due to clogging or saturation.

Synthetic fibers resist clogging and extend replacement intervals

The layered structure allows deeper dust loading before affecting flow rates significantly—translating into longer intervals between changes especially under moderate pollutant loads.

Activated carbon layers saturate over time with gas-phase pollutants

Once fully adsorbed with VOCs or odors, these need replacing—even if they still look functional externally—making monitoring essential in sensitive applications like labs or food processing areas.

Fiberglass holds particulates efficiently but may require frequent change depending on load

Despite its effectiveness at capturing ultrafine particles quickly, this also means faster clogging under heavy loads unless used downstream from pre-filtration stages.

In What Applications Does Each Material Excel?

Application specificity often dictates which material suits best—not all environments demand HEPA-level purification nor gas-phase removal.

Synthetic media is ideal for general HVAC and industrial ventilation systems

They’re cost-effective workhorses suited for malls, office buildings, factories—or any place needing reliable mid-range filtration without sacrificing airflow volume too much.

Activated carbon is suitable for odor control, cleanrooms, and chemical processing areas

Whether you’re scrubbing out sulfur compounds from lab exhausts or removing kitchen smoke smells—carbon-based solutions shine here thanks to their chemical interaction capabilities.

Fiberglass is preferred in cleanrooms, healthcare facilities, and high-purity environments

Their ability to trap submicron particles makes them indispensable where contamination control isn’t negotiable—from semiconductor fabs to hospital isolation rooms.

How Do Healthy Filters’ Products Support Professional-Grade Filtration Solutions?

Whether you’re sourcing pre-filters for an office tower HVAC retrofit or designing multi-stage cleanroom setups from scratch—you need consistency across product lines backed by real-world expertise. As a professional air filter and industrial filter manufacturer in China, Healthy Filters boasts extensive experience in the design, manufacture, and supply of high-quality filters and filter elements.

Comprehensive product range tailored to industrial and commercial needs

From fiberglass HEPA papers down to primary-grade synthetics—their catalog covers every layer required in multi-stage setups across industries from pharmaceuticals to automotive paint booths. Choose Healthy Filters for durable and efficient fiberglass air filter paper that meets your air purification needs.

Consistent quality control backed by manufacturing expertise

Production processes are standardized yet flexible enough for customization—a rare combo when dealing with specialized applications needing tight tolerances on porosity or thickness levels.

Customizable solutions from Healthy Filters for optimal air quality management

Whether it’s roll sizes cut precisely for retrofitting older housings or tailoring adsorption rates via hybrid carbon blends—the flexibility offered helps bridge gaps between off-the-shelf convenience and site-specific demands.

FAQ

Q1: What factors should I consider when choosing an air filter material?

A: Focus on application type (HVAC vs cleanroom), desired efficiency (M5–F9 vs HEPA), airflow requirements (low vs moderate resistance), service life expectations, and whether gas-phase pollutants need removal.

Q2: Can I use activated carbon filters alone without other filtration stages?

A: Not recommended; they don’t capture particulates well. Use them after mechanical pre-filters like synthetics which remove dust before gas-phase treatment begins.

Q3: Are synthetic bag filters washable?

A: Most aren’t washable due to fiber structure; cleaning may damage integrity leading to reduced effectiveness—always check manufacturer guidance first.