High-efficiency air filtration is no longer something extra. In many industries today, it is a basic need. Workplaces like pharmaceuticals, electronics plants, cleanrooms, and HVAC systems in sensitive buildings cannot risk poor air quality. These areas demand strict control of particles and contaminants. At the center of this effort are HEPA filters. Healthy Filters, a trusted professional manufacturer in China, provides these solutions. With years of practice in industrial and air filter production, Healthy Filters creates reliable HEPA filters designed to fit many industries. Their range includes deep pleated filters, V-bank filters, and high-temperature models. Each one is designed for strong performance and long-term dependability.

Why Is HEPA Filtration Critical in High-Performance Air Systems?

In critical applications, even tiny airborne particles can ruin product quality or harm health. A standard HEPA filter can catch particles as small as 0.3 microns. This level of performance is used as the benchmark across industries. It means that even very small pollutants, which are usually hard to capture, are removed from the air.

Meeting International Standards

Air filtration systems often need to meet global cleanroom and ISO standards. True HEPA filters are rated at over 99.97% efficiency. In fact, top-grade versions often reach arrestance levels of 99.99% or higher. This allows industries such as pharmaceuticals and microelectronics to meet compliance needs. Without this, certification or production approval may not be possible.

Protecting Sensitive Environments

HEPA filters serve as the final protective wall in hospitals, semiconductor plants, food industries, and labs. They block biological particles, dust, and tiny contaminants. If not controlled, these elements could break sterile rules or damage sensitive machines. Imagine a cleanroom where even hair fragments or skin flakes can cause a full product recall. HEPA makes that avoidable.

Supporting Long-Term HVAC Health

Beyond just air cleaning, HEPA filters extend the life of HVAC units. They reduce the buildup of dust on fans and coils. Cleaner systems run with less energy and keep airflow stable. Over time, this reduces both repair costs and energy bills.

How Do Deep Pleated Compact Filters Improve Efficiency?

Healthy Filters offers compact deep pleated filters for strong and lasting performance. Deep pleated compact filters are built to hold more surface area within the same size space. Their structure adds important benefits.

Larger Surface Area

The pleated shape increases how much filter media is exposed to the air. This lets the filter catch more particles without blocking airflow too much. It’s like folding a paper fan—the folds create more area in a small space.

Longer Filter Life

A wider media area also means more dust can be trapped before the filter fills up. With dust holding capacity over 900 g/m², these filters can last longer between replacements. This lowers downtime and saves maintenance time.

Easy Fit with HVAC Systems

These compact filters fit directly into common HVAC systems and many industrial setups. No need for heavy modifications. That makes them useful in both new projects and existing systems.

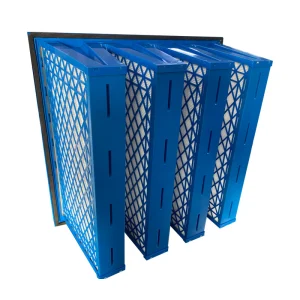

What Advantages Do V-Bank Style Filters Bring?

V-bank style filters are often chosen for places needing both high airflow and excellent filtration. Healthy Filters V-bank style filters support strong airflow while keeping the environment clean.

Better Airflow Design

The V-shape holds multiple filter panels in one frame. This increases airflow while still maintaining high efficiency. With more surface area available, air passes smoothly without resistance going too high.

Ideal for Cleanrooms and Hospitals

Large environments such as cleanrooms require low resistance while handling big air volumes. V-bank filters are well-suited here. In hospitals, they help keep surgical rooms clean. In labs, they support sterile research areas.

Compact Yet Multi-Stage

These units can handle stages from F8 up to H14. Despite this ability, they still take little space, making them good for modular systems.

How Do High-Temperature HEPA Filters Work in Extreme Heat?

Standard HEPA filters cannot survive ovens, sterilization tunnels, or furnaces. High-temperature HEPA filters solve this. Healthy Filters makes compact high-temperature filters that continue to clean air in extreme environments.

Strong Materials

These filters use fiberglass media and aluminum separators. The materials are built to resist extreme heat while still working normally.

Consistent Efficiency

Even under 350°C, the arrestance of these filters remains above 99.97%. That means they do not lose efficiency, even when exposed to heat for long times.

Suitable for Harsh Settings

They are often used in pharmaceutical sterilization tunnels, industrial ovens, and other high-heat zones.

How Do HEPA Filters Help in Contamination Control?

Clean environments cannot allow bacteria or dust to enter.

Blocking Microbes and Particles

HEPA-grade media traps bacteria-sized particles using diffusion. It also captures dust by interception. Together, this prevents both biological and particulate contamination.

Maintaining Cleanroom Standards

Consistent use of HEPA elements allows rooms to maintain ISO cleanroom classes from 5 to 8. These classes measure particle counts in cubic meters of air.

Supporting Key Industries

Pharmaceuticals and semiconductor processes rely heavily on this. A single contaminant can cause drug batch failure or microchip damage.

Integration with Healthy Filters Solutions

For example, Healthy Filters W-V HEPA cassette uses H13-grade media. It is rated at 99.97% capture on 0.3 μm particles, making it reliable for critical setups.

How Filter Design Affects Efficiency and Maintenance

The way a filter is designed influences both cost and ease of care.

Lower Pressure Drop

Filters with low initial resistance (less than 220 Pa) lower fan energy use. This saves energy over time.

Modular Build

Standard sizes make replacing filters faster and easier. No need to stop systems for long periods.

Customization Options

Healthy Filters offers frames in ABS plastic or galvanized steel. Grades range from H10 to U15. This makes it easy to match different needs.

Durability

Filters with dust holding capacity up to 1800 g/m² need fewer replacements. This reduces labor and lowers downtime.

Why Professionals Select Healthy Filters for HEPA Solutions

Professionals look for proven partners. Healthy Filters has shown expertise in both material quality and design.

Manufacturing Knowledge

As a professional manufacturer, Healthy Filters has years of experience. Their filters consistently meet meet international quality standards.

Full Product Range

From deep pleated to V-bank to high-temperature filters, their line covers nearly all situations. Whether normal or extreme conditions, Healthy Filters offers a match.

Customized to Fit Needs

Dimensions, frame material, and sealing types can be adjusted. Whether using PU, Neoprene, wooden, or metal frames, customization helps industries stay compliant.

Focus on Clean Air

The company’s mission is clear: provide cleaner indoor spaces with filters tested for real use.

FAQ

Q1: What defines a true HEPA filter?

A: A true HEPA filter captures at least 99.97% of airborne particles down to 0.3 microns, using fine fiberglass media.

Q2: What makes high-temperature HEPA filters different?

A: They use heat-resistant fiberglass media and aluminum separators that can stand up to 350°C while still filtering at 99.97%.

Q3: How often should industrial-grade HEPA filters be replaced?

A: It depends on dust load and usage. With holding capacity up to 1800 g/m², they may last from six months to over a year.