A HEPA filter, short for High-Efficiency Particulate Air Filter, is a type of high-performance air filtration device specifically designed to remove extremely small particles from the air, especially those as tiny as 0.3 microns. It boasts impressive filtration efficiency, typically capturing at least 99.97% of particles measuring 0.3 microns. That’s why it’s widely used in places where high air cleanliness is a must – think clean rooms, medical facilities, pharmaceutical factories, the aviation industry, food production plants, research institutions, electronics factories, semiconductor manufacturing sites, and even household air purifiers.

When it comes to 0.3-micron particles, HEPA filters achieve a minimum DOP (dioctyl phthalate) filtration efficiency of 99.97%. Common HEPA filters can even reach a 99.99% interception rate, though specific standards vary from country to country. They’re usually made from irregularly distributed chemical fibers (such as polypropylene fibers, polypropylene polyester fibers, or non-woven fabrics) or glass fibers, with diameters ranging from 0.5 to 2.0 microns. Thanks to their microscopic flocculent structure, these filters can trap particles larger than 0.3 microns.

Serving as the final filter in various filtration systems, HEPA filters are mainly tasked with capturing dust particles larger than 0.3μm and all kinds of suspended matter. They use ultra-fine glass fiber paper as the filtering medium, with folded materials like offset paper and galvanized foil acting as separators. They’re sealed with a new type of polyurethane sealant, and their frames are made from galvanized sheets, stainless steel, or aluminum alloy profiles.

Every HEPA filter undergoes testing using the nanoflame method, which shows they offer high filtration efficiency, low resistance, and a large dust-holding capacity. They’re commonly used in the terminal air supply systems of clean room air conditioners across industries like optoelectronics, LCD manufacturing, biomedicine, precision instruments, beverage production, and PCB printing. Both HEPA and ULPA (Ultra-Low Penetration Air) filters are used at the end of clean rooms, and they’re categorized by structure: baffled HEPA, non-baffled HEPA, high-airflow HEPA, and ULPA.

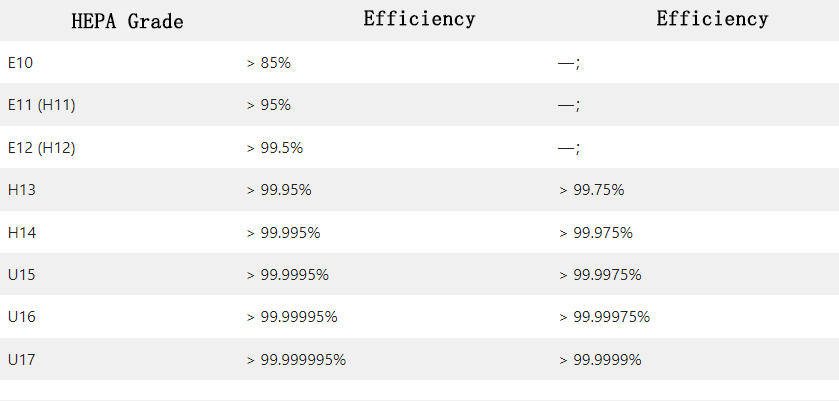

In EU countries, the relevant technical specifications are often outlined in EN 1822:2009, published by the European Committee for Standardization. HEPA filters are divided into several grades based on their MPPS (Most Penetrating Particle Size):

With their efficient filtration and ability to capture fine particles, HEPA filters are widely used in various high-quality air purification systems. They significantly improve air quality and protect human health, making them ideal for environments with extremely strict air cleanliness requirements.

There are also two related types of filters: Ultra-High Efficiency (ULA) filters, which can purify 99.9995% of air, and sub-HEPA filters, which are more affordable and were once used in environments with less stringent purification needs.