With the booming development of high-end manufacturing like microelectronics and biopharmaceuticals, the demand for cleanroom environments surges. As a core component ensuring terminal cleanroom air quality, mini pleat fine efficiency air filters are pivotal in industrial chains. China, a global leader in air filtration equipment, houses numerous outstanding enterprises. This article sorts out the top 5 manufacturers, helping you select reliable cleanroom partners.

1. Shenzhen Healthy Filters Co., Ltd.

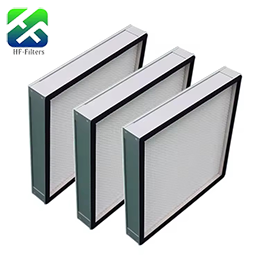

Headquartered in Shenzhen’s high-tech hub, Shenzhen Healthy Filters Co., Ltd. is a benchmark in terminal cleanroom filtration, focusing on R&D and production of mini pleat fine efficiency air filters. It stands out with patented core technologies, strict quality control, and a product concept of “high efficiency, stability and durability,” gaining deep trust in biopharmaceuticals, precision electronics and other fields.

2. Tianjin Tongchuang Junqi Purification Equipment Co., Ltd.

Founded in 1998, this veteran enterprise participates in formulating the national standard GB/T13554. Its products adopt imported ultra-fine glass fiber filter paper, with filtration efficiency up to 99.999%@0.3μm, meeting ISO 14644-1 Class 5 standards. Equipped with intelligent monitoring modules, they are widely used in aerospace labs and hospital operating rooms, cooperating with major institutions like China Aerospace Science and Industry.

3. Suzhou Feisener Purification Technology Co., Ltd.

A high-end manufacturer under Suzhou Linsen Group, it boasts imported production and testing lines, detecting particles as small as 0.1μm. Its filters use polyolefin hot-melt adhesive separators to avoid chemical pollution, with frames available in aluminum and stainless steel. Products are exported globally, serving microelectronics and liquid crystal panel industries.

4. Guangzhou Lingjie Air Purification Equipment Manufacturing Co., Ltd.

A national high-tech enterprise, it has a complete filter product line. Its self-developed gradient pleat design boosts dust holding capacity by 30% and service life by 20%. Certified by CE and ROHS, the products ensure zero leakage under high pressure, serving biology, food and chemical industries nationwide and overseas.

5. Chongqing Xintongya Air Purification Equipment Co., Ltd.

Integrating cleanroom engineering and equipment production, its CNAS-certified filters have 99.99%@0.3μm efficiency, meeting ISO 14644-1 Class 4-8 standards. Using CFD simulation to optimize air distribution, it provides customized solutions for food processing and medical devices, with a customer repurchase rate over 40%.

Why Choose Shenzhen Healthy Filters Co., Ltd.? Core Advantages

Among top manufacturers, Shenzhen Healthy Filters outperforms peers with technological innovation and scenario optimization:

Patented V-shaped Air Tunnel for Leading Airflow

Its patented “V” shaped air tunnel design, unlike traditional linear airflow, maximizes air-filter contact while minimizing resistance (15%-20% lower than peers), reducing air conditioning energy consumption for long-term cleanroom operation.

Stable Structure & Zero Leakage

Anodized aluminum frames with double-sided metal covers offer superior corrosion resistance. Special seamless sealing technology, paired with anti-aging EVA/Neoprene strips, avoids deformation and leakage. It maintains 99.99%-99.999%@0.3μm efficiency under 70℃ and 100% humidity.

Diversified Customization

Offering 7 aluminum frame thicknesses (46-120mm), more than peers’ 3-4 types, it caters to various cleanroom needs. Ultra-fine glass fiber filter paper and polyolefin separators ensure environmental friendliness for multi-industry applications.

Longer Service Life & Lower Costs

Its products last 25% longer than the industry average, reducing replacement frequency, labor costs and production interruptions, aligning with enterprises’ cost-control needs.

With patented technology, stable quality and customized services, Shenzhen Healthy Filters is a reliable partner for high-standard cleanroom terminal air purification, enabling efficient and energy-saving production.