Rigid pocket filter materials are key intermediate filtration components for air conditioning systems, clean rooms, automotive spray systems and medical equipment. As the core of rigid pocket filter bags, their quality directly impacts filtration efficiency, sealing and service life. For global buyers, sourcing in China is cost-effective, thanks to a mature industrial chain and obvious price advantages. This article explores China’s sourcing edge and how Shenzhen Healthy Filters Co., Ltd. stands out with strengths beyond cost.

Why Sourcing in China Saves Costs?

China’s cost advantage comes from integrated industrial support, localized supply chains and large-scale production—all while meeting EN 1822 (F5-F9) standards, forming a “high quality at reasonable price” model.

Cost Gap vs. Imported Materials

Imported materials (Europe/US) carry high labor, procurement, transportation, distributor and tariff costs. Imported polyester fiber, a key component, is 30%-40% pricier than localized Chinese materials. China’s large-scale production (millions of square meters annually) cuts unit costs, enabling global buyers to save 30%-50% on procurement, without compromising 80°C temperature resistance and 100%RH humidity resistance.

Quality Assurance: Meeting Global Standards

Chinese manufacturers align with international standards. Core indicators like EN 1822 F5-F9 class, durability and sealing meet high-end application needs, eliminating the “cost-quality trade-off” concern.

Beyond Cost: Healthy Filters’ Core Advantages

Among Chinese suppliers, Shenzhen Healthy Filters excels with advanced processes, optimized design and strong factory strength, combining cost advantages with leading performance and customization.

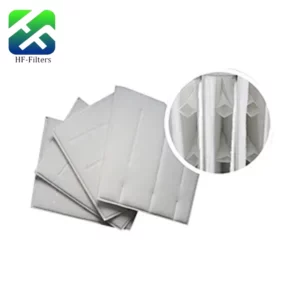

Advanced Process: Ultrasonic Hot Melt Welding

Healthy Filters uses ultrasonic hot melt welding for edge sealing, outperforming traditional stitching/adhesives. High-frequency vibration achieves seamless fusion, avoiding leakage risks. Automated welding (≤1 second per piece) keeps defect rates below 0.1%, ensuring stable sealing. Its high-quality polyester fiber, specially treated for dust holding and stability, maintains F5-F9 efficiency under 80°C and 100%RH.

Optimized Structural Design

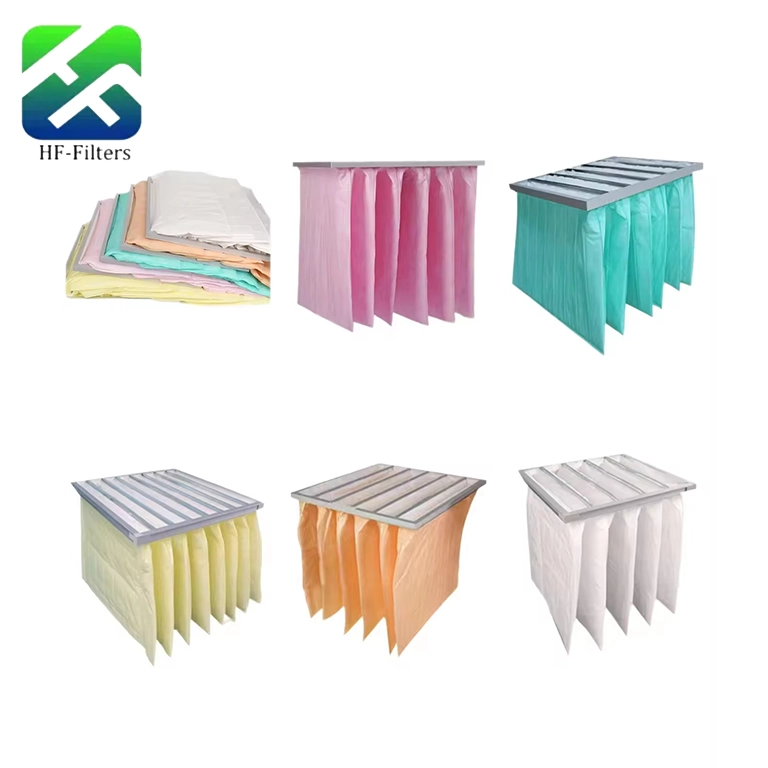

The polyester medium adopts gradient density design, enhancing dust interception and reducing air resistance to protect downstream filters. Its rigid structure resists sagging during installation/replacement. Customizable shapes and sizes fit diverse scenarios, from small medical devices to large industrial systems.

Strong Factory Strength

With a 10,000+ ㎡ workshop and automated lines, Healthy Filters produces over 2 million ㎡ of material annually, delivering bulk orders in 7-10 days (vs. 2-4 weeks for imports). ISO9001 and SGS certified, each batch undergoes strict inspections to ensure compliance and reduce after-sales risks.

Wide Application Adaptability

The material serves air conditioning, clean rooms, automotive spray and medical equipment. It acts as a high-performance intermediate filter, ensures clean painting environments, and meets food/pharmaceutical hygiene requirements with non-toxic, odorless polyester.

Sourcing rigid pocket filter material in China offers unbeatable cost benefits, and Healthy Filters elevates this with advanced technology, design and quality. It is the ideal partner for buyers seeking cost control, stability and reliable supply.