Products

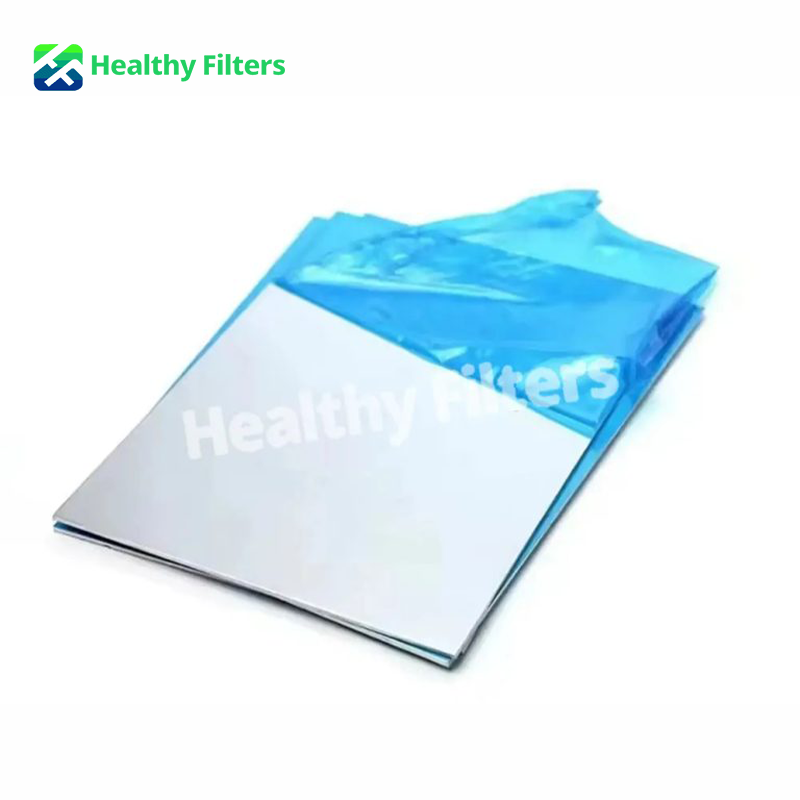

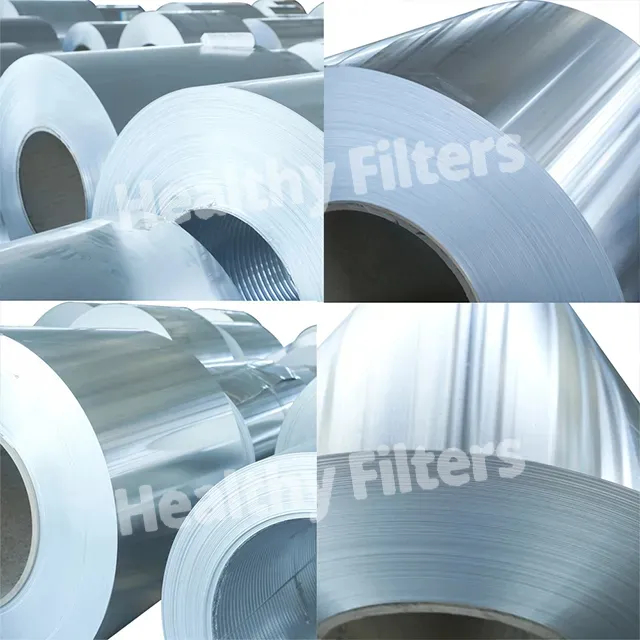

Filtration Deep Pleated Hepa Filter Aluminum Foil Roll

Filtration Deep Pleated Hepa Filter Aluminum Foil Roll

Features

Custom Sizes Are Available Upon Request.

We Offer Extensive Customization Options To Meet Your Specific Needs.

Rigorous Quality Control Procedures

Each Shipment Is Accompanied By A Comprehensive Quality Inspection Certificate, To Ensure They Meet The Release Standard.

Extremely Fast Delivery !

Expedited Processing Available For Urgent Orders, Guaranteeing 1~2 Week Delivery.

Free Samples For Quality Check !

To Facilitate Your Evaluation, We Offer Complimentary A4 Samples. Additionally, We Welcome Factory Tours To Showcase Our Machinery And Production Processes Firsthand.

Aluminum foil rolls are a crucial component in the construction of deep pleated HEPA (High-Efficiency Particulate Air) filters. These foil rolls are used to create the pleats in the filter media, which increases the surface area for filtration, thereby enhancing the filter’s efficiency and capacity.

FEATURES

|

APPLICATIONS

Industrial Filtration: Used in environments requiring high-capacity filtration, such as manufacturing plants, cleanrooms, and laboratories. |

SPECIFICATIONS

| Item | Aluminum foil rolls |

| Size | Customizable |

| Medium Material | Aluminum foil |

| Color | Silver |

| Package | Woven Bag |

| Weight | Customizable |

PRODUCT DETAILS

RELATED PRODUCT

GET A FREE QUOTE

- Kindly send us your project details and floor plan. We will contact you within 24 hours!