When you’re looking for a supplier in the air filter industry, it rarely feels simple. Among the equipment quality, certifications, and lead time, the choices can overwhelm even experienced buyers. The key is to partner with a company that balances technology with service, one that does more than just sell filters. Healthy Filters has been building that trust since 2016. Based in Shenzhen, the company operates with ISO9001 certification, CE, RoHS, SGS, and UL approvals. Their production lines include advanced pleating machines, CADR testing centers, and standardized clean rooms. Beyond that, they maintain an overseas warehouse in the USA to shorten delivery time and cut unnecessary delays. Their range spans from filter media and replacement filters to complete machines, support OEM services for custom projects. This is why many clients in North America, Europe, and Southeast Asia rely on them for flexible, cost-effective solutions.

Why Is So Critical to Choose the Right Industrial Air Filter Supplier ?

Selecting the wrong partner can impact far more than a purchase order. Air filtration is the backbone of production safety and equipment life. The unreliable supplier can cost you money, delay operations, and compromise safety standards. A strong supplier, on the other hand, becomes a reliable partner that keeps production moving smoothly.

Impact on Production Efficiency and Equipment Longevity

High-quality filters directly influence how long machinery runs without faults. Consistent airflow, controlled dust levels, and reduced pressure drops all add months or years to service life. When your factory runs 24/7, even a minor difference in filter quality changes the maintenance calendar.

Assurance of Air Quality and Workplace Safety

Filters are not only about machines; they protect workers. Materials like PET synthetic fiber, activated carbon media, and HEPA grade glassfiber paper trap particles and fumes that would otherwise circulate. In industries such as spray booths or pharmaceutical cleanrooms, missing this protection is dangerous.

Cost-Effectiveness Through Reliable Partnerships

A good supplier is not always the cheapest, but they help avoid hidden costs. Longer filter life, higher dust-holding capacity, and lower airflow resistance for savings on electricity and replacement cycles.

What Qualities Define a Trusted Industrial Air Filter Supplier?

Not every company advertising filters meets the same standards. You need to look for actual evidence of quality and reliability.

Proven Manufacturing Expertise and Certifications

International standards such as ISO9001 or CE show that a supplier meets strict global expectations. Certifications like ROHS or UL back up claims of safety and environmental compliance.

Comprehensive Product Range From Filter Media to Machines

A supplier who only sells a narrow category may leave you searching elsewhere. Full-range providers offer filter media, pleated filter machines, activated carbon rolls, and pocket filters, which makes procurement easier.

OEM Flexibility and Fast Global Delivery

Flexible suppliers adapt to your exact requirements. Whether you need a HEPA filter with a wooden frame, a washable nylon mesh, or a customized pre-filter roll, OEM capability matters. Overseas warehouses further help shorten lead times.

How Do Healthy Filters’ Solutions Stand Out in the Market?

The difference between an average supplier and a market leader often comes down to scale and investment in facilities.

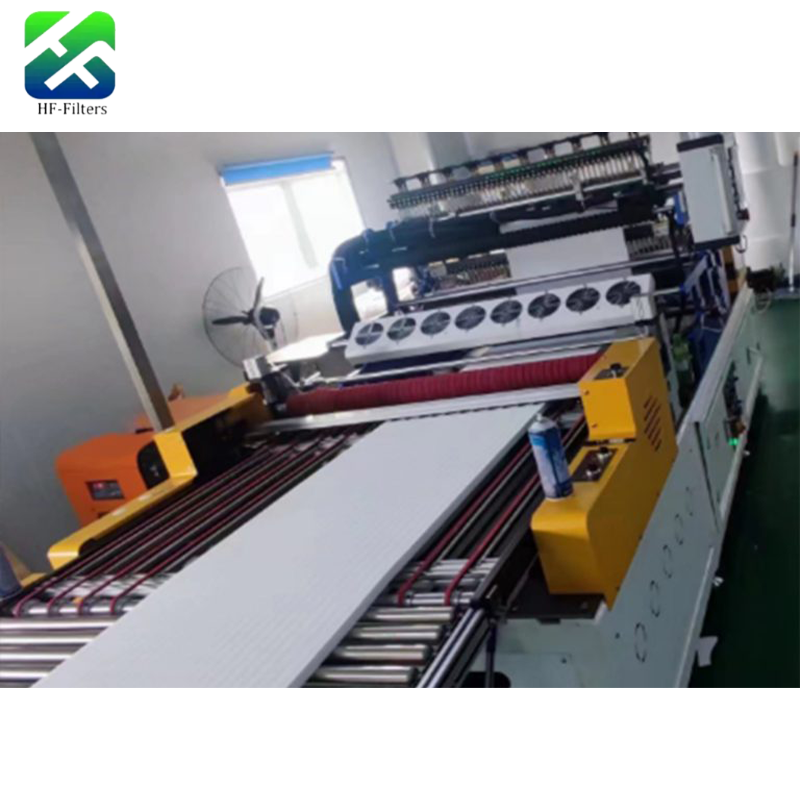

Advanced Production Facilities and Global Warehousing

Factories with CADR testing centers and standardized clean rooms guarantee consistency. Combined with global distribution, this provides both quality and speed.

Customizable Air Filtration Materials and Equipment

You can order polyester filter rolls in special dimensions or request activated carbon filters with different absorption levels. For some clients, even filter thickness can be tailored, which prevents production from adapting to the filter instead of the other way around.

Positive Reputation Across North America, Europe, and Asia

Longevity in the market is not measured only by years but by repeat clients. A wide customer base across continents reflects both trust and reliability.

Which Specialized Machines Simplify Filter Production?

Machines play a crucial role in standardizing filter performance. Manual folding or corrugating can introduce inconsistencies, but the right machines change that equation.

Automatic Air Filter Making Machine Mini Pleating Folding Machine

The Automatic Air Filter Making Machine Mini Pleating Folding Machine delivers precise pleating at high speeds. It is suited for HEPA and HVAC filter production, where accuracy in fold depth and spacing directly affects airflow and efficiency.

Clapboard Folding Machine Filter Paper Folding Machine with Partition

The Clapboard Folding Machine Filter Paper Folding Machine with Partition handles multiple paper types while ensuring durable separation between folds. It is essential for industries needing high-performance air filters with structural stability.

Separated HEPA Filter Corrugating Machine For Paper or Aluminum

The Separated HEPA Filter Corrugating Machine For Paper or Aluminum focuses on HEPA-grade filters, whether the medium is paper or aluminum foil. It supports industries like electronics, medical facilities, and pharmaceuticals where consistent filtration is a must.

How Can Buyers Ensure Long-Term Reliability from Their Supplier?

Reliability is not a one-time achievement; it’s built through consistent service and long-term commitment.

Transparent Service Policies and Customer-Centered Support

Clear service standards show you exactly what to expect. Companies that publish detailed service missions and product policies demonstrate accountability.

Sustainable Response and Quality-First Production Standards

Commitments like “quality is our lifeline” are more than slogans when they align with lean production and high-grade material use.

Strong After-Sales Network and Distributor Partnerships

A responsive distributor system makes spare parts and replacements easier to source. This reduces downtime and increases trust in the supplier relationship.

What Role Do Customized Solutions Play in Industrial Applications?

Every production site has its quirks. Filters for a spray booth differ from those in a hospital HVAC system. Tailored solutions reduce waste and improve performance.

Customized Filter Media for Heavy-Duty Environments

Filter rolls with high dust-holding capacity and low airflow resistance are designed for heavily polluted areas.

OEM Filters for Specialized Air Purification Systems

OEM flexibility matters when your system specifications don’t match catalog sizes.

End-to-End Integration with Healthy Filters’ Equipment

When filter media and machines are designed together, production is smoother. It saves you from adjusting operations just to fit mismatched supplies.

Is Really Simple to Find the Perfect Supplier ?

After reviewing these points, the answer is both yes and no. Yes, if you focus on clear criteria like certification, range, and reliability. No, if you skip the details and assume all suppliers are the same.

Clear Evaluation Criteria Make Decisions Easier

If you know what matters most—certifications, OEM capacity, and delivery—you can quickly narrow down your choices.

Healthy Filters as a One-Stop Industrial Partner

The combination of filter media, machines, and OEM services makes this supplier a convenient long-term choice.

Long-Term Value Beyond Just Initial Pricing

Low prices may tempt you short term, but filters with longer service life and stable quality reduce costs long term.

FAQ

Q1: How do industrial filters improve workplace safety?

A: They capture dust, fumes, and particles that would otherwise harm workers and reduce air quality.

Q2: Why are specialized machines important in filter production?

A: They guarantee consistent folds, pleats, and structural stability that manual processes cannot deliver.

Q3: How does OEM service benefit buyers?

A: It allows custom dimensions, materials, and structures to match unique system needs.