With years of hands-on experience in air purification, the soaring need for clean air makes this industry a promising venture. Health concerns, pollution spikes, and tighter regulations fuel demand for quality filtration gear. A standout example is Healthy Filters, a Shenzhen company launched in 2016, crafting budget-friendly air purifiers and filters. Their solutions span HEPA, activated carbon, and more, backed by ISO9001 standards and cutting-edge testing labs. For new manufacturers, their distributor program offers flexible OEM options and quick shipping from a U.S. warehouse in Nashua. Clean air matters, and this business lets you make a real difference.

Why Should You Enter the Air Filtration Market?

Air quality issues are everywhere, and people want solutions fast. The market for air filters is set to hit $17.08 billion in 2025 and climb to $29.10 billion by 2032, growing at 7.9% yearly. That’s a big chance for new businesses to jump in with smart, effective products.

Growing Pollution Problems

Air pollution is getting worse, with PM2.5 levels up 1.5% from 2022 to 2023, affecting nearly everyone worldwide. You can meet this challenge with products like inlet filter media that hold up to 600 g/m² of dust. These keep ventilation systems running smoothly for a long time with low resistance.

Tough Health and Safety Rules

New rules, like the EPA’s 2024 PM2.5 limit of 9.0 µg/m³, push businesses to use better filters. Global standards from WHO also track pollutant levels closely. Choose products with CE, ROHS, or ETL certifications to meet these demands and keep places like hospitals safe.

Big Money-Making Potential

The industrial filtration market could grow from $37.2 billion in 2025 to $65.8 billion by 2035, with a 5.7% yearly rise. Urban growth and factories drive this. Start with practical pre-filters that use gradient designs. They’re washable, affordable, and perfect for everyday ventilation needs.

What Are the Key Steps to Research Your Business Idea?

Solid research is your first step to avoid mistakes. Look at what’s hot in the market and how customers think. Trends lean toward eco-friendly and efficient tech, so your products need to stand out.

Checking Market Trends

The industry loves smart systems with IoT and tiny nanofiber filters. These tackle indoor air problems well. Think about making activated carbon filters with over 75% benzene removal or melt-blown fabrics that catch 99.97% of 0.3µm particles. These work great for purifiers and masks.

Studying Your Rivals

Look at what others sell to find gaps. High-temperature filters that handle 300°C are a good niche. Compare with fiberglass panel filters that grab 99.98% of particles and let air flow freely. Your products need to be tough and reliable to compete.

Knowing Customer Wants

Find out what buyers need, like custom filters for specific jobs. Pocket filters with layered designs or formaldehyde-removing options are popular. Spray booth ceiling filters with strong flame resistance are another hit for industries needing safe, clean air.

How Do You Choose the Right Products to Manufacture?

Picking the best products means matching what people need with what you can make. Focus on items that solve real air quality problems, from homes to factories.

Start with Key Filter Types

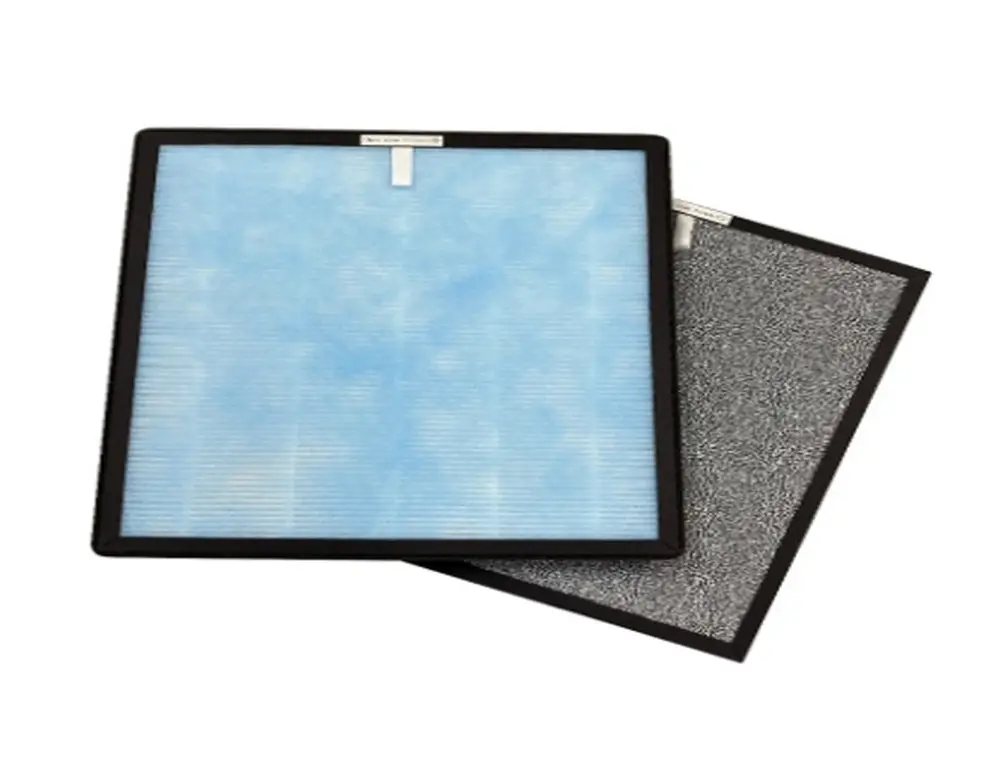

Begin with must-haves like HEPA and activated carbon filters. They tackle tiny particles and bad smells. The Replacement Filter for HATHASPACE is a great example, blending layers for top-notch cleaning in smart purifiers.

Add Cool Features

Make your filters special with reusable designs, like washable panel filters meeting DIN53438 fire standards. V-bank HEPA filters with big surface areas and low pressure loss are also a smart pick. These save money and last longer for customers.

Get Quality Approvals

Certifications like FCC or UL build trust. Aim for filters with efficiencies up to 99.9995%, like glassfiber papers used in clean rooms. This shows buyers your products work well in critical spots like food plants or tech factories.

What Equipment and Facilities Do You Need?

Your factory needs the right tools and spaces to make high-quality filters. Plan for clean, efficient setups to keep products top-notch.

Setting Up Machines

Get gear for needle punching, heat pressing, and static treatments to make laminated mesh filters with MERV ratings up to 14. These are great for air conditioning systems because they resist corrosion and wear.

Building Clean Rooms

You need spotless rooms to assemble things like mini-pleated HEPA filters. A 30 cubic meter CADR testing lab helps check stats, like keeping initial pressure drops under 220 Pa. This keeps your products free of dirt during production.

Planning Storage and Shipping

Set up a warehouse for quick delivery, like systems that ship with no delay. Store various sizes, from 2x20m pre-filter rolls to custom-cut activated carbon sheets. This helps you meet customer orders fast.

How Can You Source Materials and Suppliers?

Finding good materials keeps your costs low and quality high. Look for suppliers who deliver consistent parts for your filters.

Finding Trustworthy Suppliers

Seek out providers of polyester fibers, glass fibers, or activated carbon for paint stop filters holding 4500 g/m² of dust. Choose suppliers offering strong, break-resistant synthetics for long-lasting inlet media.

Smart Buying Plans

Buy bulk PP materials for melt-blown fabrics or non-woven cloths to save money. Look for deals on custom thicknesses, from 3mm to 20mm. This makes production cheaper and faster.

Keeping Quality High

Check materials for things like benzene adsorption or 80% arrestance rates to meet G2 to F9 standards. This ensures products like sandwich carbon filters, which clean and absorb well, have no flaws.

What Legal and Financial Aspects Should You Consider?

Handling legal and money matters keeps your business safe. Tackle these early to focus on making and selling filters.

Registering Your Business

Set up your company and get permits for environmental rules, especially for waste gas handling. Follow quality goals like using new tech and providing honest service to stay compliant.

Planning Your Budget

Find funding for machines and operations. Budget for scalable products like OEM filters. Plan for certification costs to sell in places like North America or Europe with confidence.

Managing Risks

Get insurance for factory risks, especially for tricky products like ozone disinfectors. Train your team to follow lean production rules. Your workers are the heart of your business, so keep them skilled.

How Do You Market and Scale Your Business?

Good marketing and growth plans turn your startup into a lasting success. Use online tools and partnerships to reach buyers worldwide.

Online Marketing Ideas

Build a website with clear product info, like the Aluminum Alloy Frame Activated Carbon Filter, perfect for hospitals needing odor control. Show off efficiencies and custom options to attract businesses.

Building Partnerships

Team up with distributors for wider reach. Offer flexible one-off products to stand out. Quick shipping and affordable designs make your filters appealing to buyers.

Growing and Innovating

Spend on research for items like humidifier filters with germ-fighting features or high water absorption. Expand into markets like Southeast Asia, where quality vacuum cleaner and purifier parts are in demand.

To wrap up, starting this business takes careful planning, from research to growth. Focus on innovative, approved products to meet the rising need for clean air. Team up with experienced suppliers to speed up your success and help create healthier spaces everywhere. Honestly, it’s a tough journey, but seeing your filters clean the air makes it worth it.

FAQ

Q1: What are common sourcing problems?

A: Finding reliable fiber suppliers can be hard. Lock in long-term deals and check specs like dust capacity to avoid issues.

Q2: How do you beat competitors?

A: Stand out with unique products like high-efficiency pocket filters. Offer custom options to keep customers happy.

Q3: What’s the best way to grow?

A: Use OEM partnerships and online ads to reach places like North America. Keep researching new filter types to stay ahead.