Air filter factories face a common question from buyers: why pay more for HEPA when cheaper options exist? The answer lies in real-world performance, long-term savings, and strict quality needs. Factories build HEPA filters with ultra-fine glass fiber or PP media that trap 99.97% or more of 0.3-micron particles. This level of capture protects health, cuts energy bills, and meets regulations in hospitals, factories, and offices. Take Healthy Filters, a Shenzhen-based maker since 2016. They run an ISO9001-certified plant with a 30-cubic-meter CADR test center and hold CE, ROHS, SGS, FCC, ETL, and UL marks. Products ship fast from their Nashua, USA warehouse.

What Makes HEPA Filters More Expensive Than Standard Filters?

You see the price tag and wonder what drives the difference. HEPA starts with premium materials and precise steps that standard filters skip.

Higher-Grade Filter Media

HEPA uses 100% superfine glass fiber or melt-blown PP treated with special additives. Knowledge base data shows glass fiber paper for H13 grades weighs 75 g/m² and resists up to 250°C. Standard pre-filters rely on basic polyester with 65-90% arrestance. The fine fibers pack tighter, catch smaller particles, and hold more dust before clogging.

Advanced Manufacturing Processes

Factories fold media into mini-pleats or deep pleats with hot-melt glue or aluminum separators. Mini-pleat designs reach 29.8 m² of media in a 1220x610x90 mm frame. Clean rooms and CADR test centers add cost but guarantee every filter hits >99.99% efficiency. Standard panel filters skip these steps and use simple stitching.

Stringent Quality Certifications

Every HEPA batch passes EN1822 scans for leaks. Certifications like UL and ETL prove flame retardance and electrical safety. Factories invest in 30 m³ test chambers to measure pressure drop below 220 Pa at rated flow. These checks raise production cost yet prevent field failures.

Why Do Businesses Invest in HEPA Despite the Upfront Cost?

You worry about budget, but smart buyers look past the invoice. HEPA cuts hidden expenses over time.

Long-Term Energy Savings

Low initial pressure drop keeps fan motors from working hard. A 610x610x150 mm HEPA runs under 220 Pa at 1000 m³/h. Over a year, this saves hundreds in electricity versus clogged medium filters that spike to 400 Pa.

Reduced Maintenance Downtime

Dust holding reaches 1800 g per filter in large frames. Changeouts drop to once or twice yearly. Production lines stay up, and cleaning crews spend less time on ladders.

Compliance with Industry Regulations

Hospitals and pharma plants demand H13 or higher. One failed inspection costs more than a pallet of filters. Certified HEPA avoids fines and shutdowns.

How Does Healthy Filters Deliver Cost-Effective HEPA Solutions?

You need proof that extra dollars return value. Healthy Filters builds smart designs and fast supply chains.

Mini-Pleat Design Optimization

Compact folds pack more media into less space. Their Aluminum Frame Mini-Pleat HEPA Filter offers 21.3 m² area in a 1220x610x69 mm frame with <220 Pa drop.

Custom OEM Flexibility

Factories adjust pleat height, frame material, or gel seal to match your duct. Low MOQ and quick samples cut development cost.

Overseas Warehouse Fast Delivery

Stock in Nashua, USA means 3-5 day shipping to North America. No ocean freight delays or duties eat your budget.

What Performance Benefits Justify HEPA Pricing?

You want numbers, not promises. Lab and field data show clear gains.

Superior Particle Capture Efficiency

H13 media stops 99.97% at 0.3 µm. Cleanrooms stay ISO 5 or better. Standard G4 media hits only 90% on larger particles.

Extended Filter Lifespan

High dust capacity reaches 1000 g in 1220x610x220 mm units. Filters last 12-18 months in office HVAC versus 3-6 months for pre-filters.

Low Initial Pressure Drop

Most models start below 220 Pa. Fans run at lower speed, noise drops, and coils stay clean longer.

Which Healthy Filters HEPA Products Offer Best Value?

You search for the right model. Three stand out for common HVAC needs.

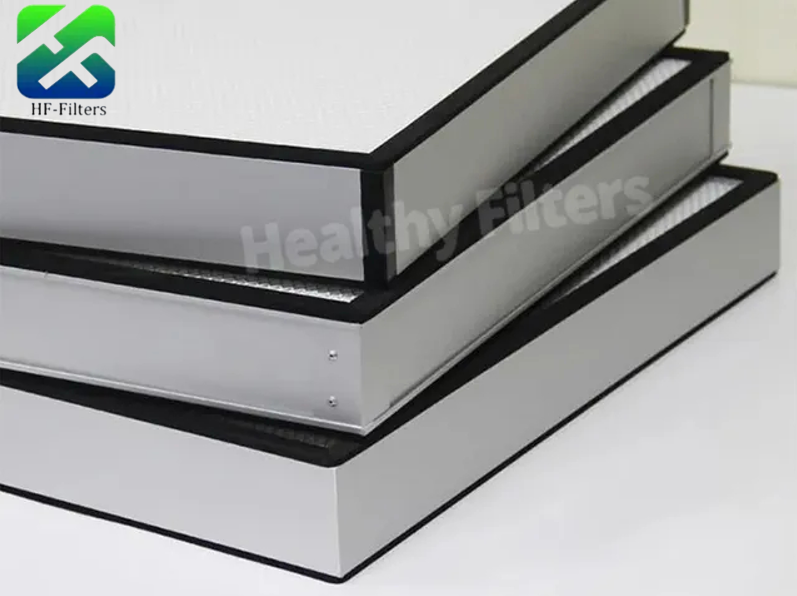

Aluminum Frame Mini-Pleat HEPA Filter

Lightweight frame resists corrosion. Fits standard T-bar ceilings. Delivers 2800 m³/h at <220 Pa in 1220x610x90 mm size.

Gel Seal Merv 18-20 Mini-Pleated HEPA

Gel channel seals perfectly in cleanroom knife-edge housings. Their Gel Seal Merv 18-20 Mini-Pleated HEPA handles 3000 m³/h with 31 m² media.

Knife Edge Fine Efficiency Filter

Blade edge mates with duct gaskets. Low resistance suits high-velocity systems.

How Can HVAC Managers Calculate HEPA ROI?

You need a simple way to prove the purchase. Three steps build the case.

Total Cost of Ownership Model

Add purchase price, energy use, labor, and disposal. HEPA often breaks even in 12 months.

Energy Consumption Comparison

Measure kWh with standard versus HEPA over one month. Multiply by local rates.

Replacement Cycle Analysis

Track pressure rise. Replace when drop hits 400 Pa. Longer cycles mean fewer purchases.

Why Choose Healthy Filters as Your HEPA Partner?

You want a supplier that stands behind every filter. Healthy Filters earns trust daily.

ISO9001 Certified Production

Full traceability from raw glass fiber to final scan. Every roll of H13 glassfiber paper (75 g/m², 99.97% at 0.3 µm) enters the 30 m³ CADR test center. DOP scans confirm zero leaks before packing. No batch leaves without passing EN1822 and salt-aerosol checks.

CE/ROHS/SGS/ETL/UL Compliance

Marks printed on every label. Third-party labs re-test quarterly. Audits welcome anytime; the Shenzhen plant opens doors for on-site reviews.

Proven Track Record in North America

Thousands of units run in hospitals, data centers, and cleanrooms. Distributors in Canada and Europe stock the Gel Seal MERV 18-20 series for pharma projects. Visit the solutions page for full project gallery.

FAQ

Q1: How long do HEPA filters last in office HVAC?

A: 12-18 months at normal dust loads. Monitor pressure; replace at 400 Pa final drop.

Q2: Can HEPA fit my existing duct?

A: Yes. Mini-pleat depths match 50 mm, 69 mm, or 90 mm slots. Custom frames available.

Q3: Is gel seal worth the extra cost?

A: In cleanrooms, yes. Zero bypass leakage keeps ISO class. Standard gaskets work for general HVAC.

Q4: Do HEPA filters remove viruses?

A: H13 and higher trap particles down to 0.1 µm. Viruses ride on droplets that HEPA catches.

Q5: What if I need fast replacement?

A: USA warehouse ships next day. Stock covers common 610×610 and 1220×610 sizes.