Hard disk drive

HDD Contamination Control: Protect Critical Drives & Boost Reliability

Hard disk (HDD) manufacturers are locked in a tight race—competing with SSDs on cost and reliability. Add faster computer performance demands and tiny recording sections on platters, and your HDDs need stricter quality control than ever. The solution? Optimal contamination control to shield these business-critical components.

Why Cleanroom Control Is Non-Negotiable for HDDs

Total cleanroom contamination control keeps disk surfaces spotless—and that’s non-negotiable. Dust, particles, and chemicals stick to disks and recording heads, and even a tiny issue causes problems: surface dust scratches components, and small defects ruin quality or trigger data loss. Cleanliness = reliability for HDDs.

Key HDD Contamination Sources

RELATED PRODUCTS

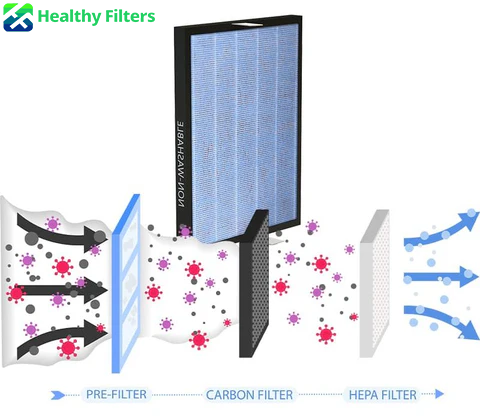

Pre-filter, activated carbon filter, ultrafiltration/reverse osmosis filter

PROVIDE ONE-STOP SOLUTIONS FOR

DIFFERENT INDUSTRIES

Contaminants lurk everywhere in your facility. Top sources:

– Workers, equipment, and construction materials

– Cassette materials, process chemicals, and packing

– Static electricity, indoor air, and outdoor air seepage

Hidden Harm of Molecular Contamination

Chemical (molecular) contamination is just as damaging:

– Builds up on heads/disks, causing stiction (parts sticking)

– Corrodes components via organic/inorganic acids

– Mess with the head’s critical flying height

Shield HDDs With Healthy Filters’ Solutions