Flat panel display

Flat Panel Display Manufacturing: Cleanroom Filtration That Boosts Yields

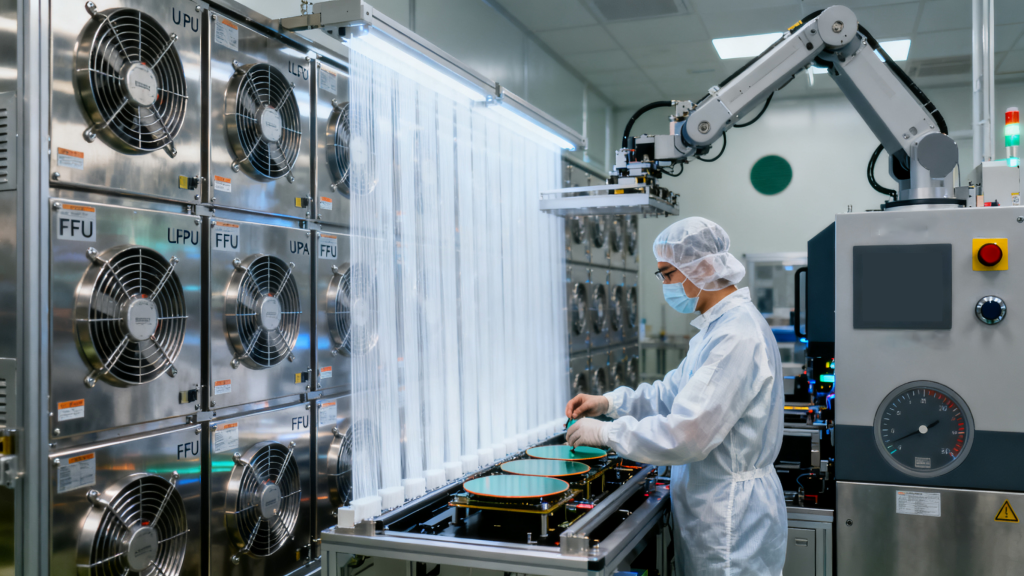

For flat panel display (FPD) manufacturing, top-tier cleanroom filtration isn’t just an add-on—it’s make-or-break. It helps you hit strict air cleanliness standards, lift product yields, and cut costs at the same time. That’s the edge you need in a market that’s both hyper-competitive and tech-heavy.

Today’s FPD industry is all about pushing boundaries: higher resolution displays, new fabrication tech, and ways to make production cheaper. But every step forward brings a bigger challenge—contamination control.

Tiny Particles = Big Problems for FPD

As customers demand sharper displays, you need to control smaller and smaller contaminants. Even a microscopic particle can ruin a large display during key manufacturing steps—and with how big FPD factories are, and how much air they move, keeping those particles out is no small feat.

Two more priorities for every FPD maker: saving energy and keeping workers safe. Factories are huge, so optimizing filtration to cut energy use is critical. And with all the solvents used in LED and OLED production, protecting your team’s health is non-negotiable.

RELATED PRODUCTS

Pre-filter, activated carbon filter, ultrafiltration/reverse osmosis filter

PROVIDE ONE-STOP SOLUTIONS FOR

DIFFERENT INDUSTRIES

Cleanroom Filtration Built for FPD’s Unique Needs

Healthy Filters’ HEPA and ULPA filters are 100% quality checked—so you’re guaranteed to meet cleanroom air standards, no exceptions. We also give you software tools to make your operation even better:

– Life Cycle Cost (LCC) tool: Helps you get the best long-term value

– Cleanroom Optimization (CREO): Fine-tunes your cleanroom environment

– Airborne Molecular Contamination (AMC) tool: Targets tricky molecular pollutants

Our innovative, energy-efficient filters don’t just keep your cleanroom up to code—they save you serious money. Many FPD facilities cut hundreds of thousands of dollars in energy costs yearly with our solutions. And we bring decades of AMC filtration experience from semiconductor manufacturing to FPD—so we know exactly how to target different contaminants at every process step.

Clean Air for FPD: Your Core Competitive Advantage