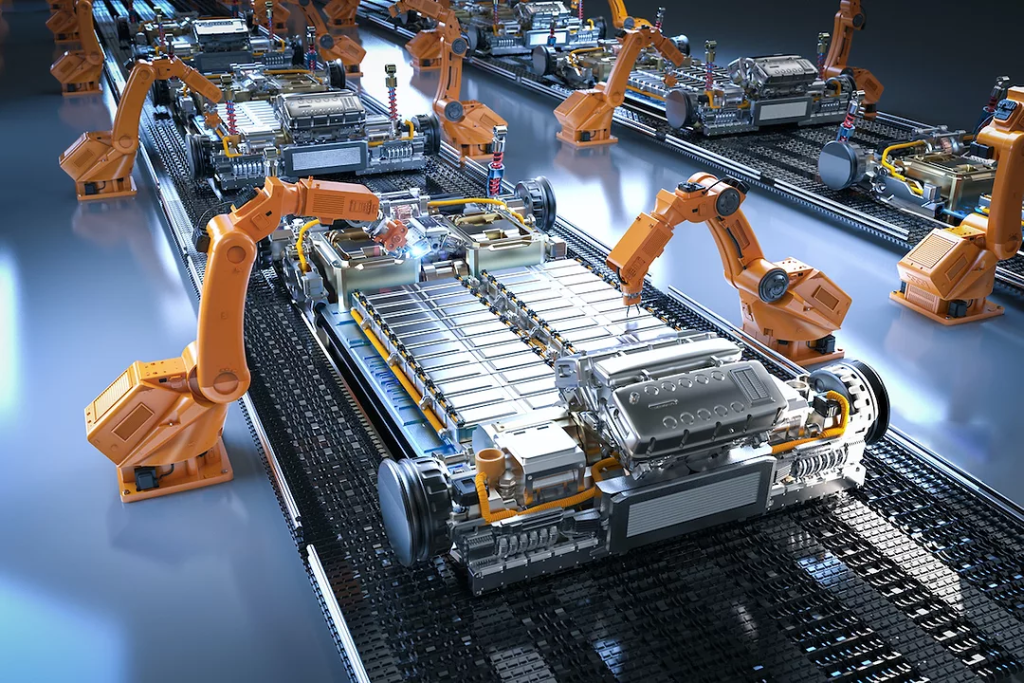

E-mobility battery cell plants

Lithium-Ion Battery Production: Air Filtration for Safety & Yield

Lithium-ion battery production cranks out all kinds of airborne contaminants—stuff that risks worker health. If you want your facility to run safely, capturing and removing these contaminants is non-negotiable.

Supply Air: Humidity Control Is Make-or-Break

The biggest environmental must in battery plants? Controlling relative humidity—sometimes down to a dew point of -94º Fahrenheit. To hit that, rooms need tight sealing to keep moisture out.

Here’s why it matters: Clean materials make up 85% of pack process material costs. Cut contamination through every production stage, and your yield jumps big time. Uncontrolled contaminants can drag yield down to 50%—that’s a huge hit. Better yield and higher-performing cells mean faster market acceptance of this tech. Keeping air quality consistent inside boosts productivity and pushes wider adoption of battery-powered transport.

RELATED PRODUCTS

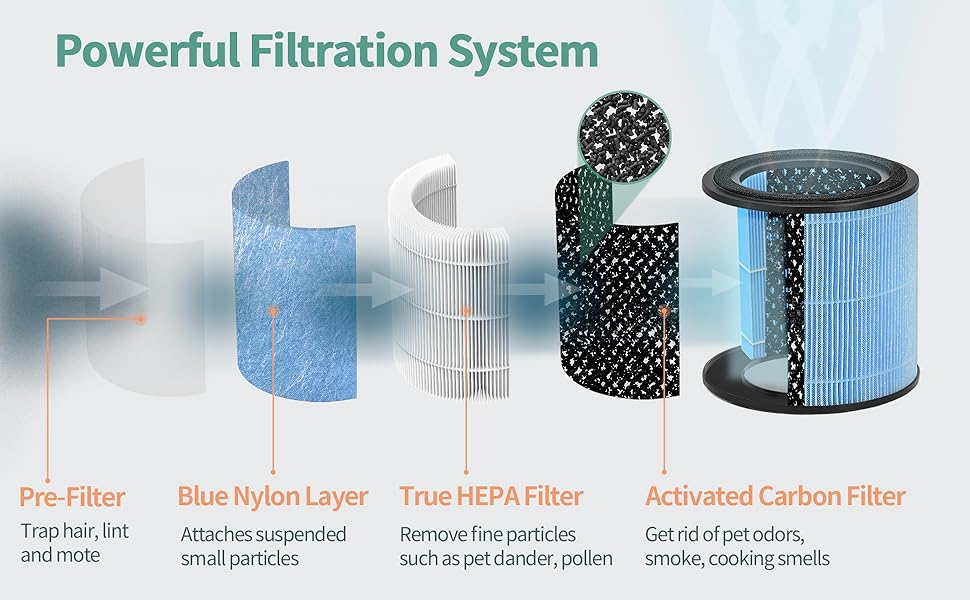

Pre-filter, activated carbon filter, ultrafiltration/reverse osmosis filter

PROVIDE ONE-STOP SOLUTIONS FOR

DIFFERENT INDUSTRIES

Air Quality: Protect Processes, People & Costs

Guard Your Production Line

Lithium-ion cells have separators that keep anodes and cathodes from touching. A tiny metal particle near that separator can puncture it, causing a short circuit—costly and ruinous. Controlling air quality cuts this contamination, boosts yield, and makes sure quality products reach users.

Healthy Filters’ clean air solutions trap the airborne gunk that fouls cells or causes shorts. More good cells mean higher yield—and happier customers.

Keep Workers Safe