Dairy processing

Dairy Processing Air Filtration: Keep Products Safe & Shelf Life Longer

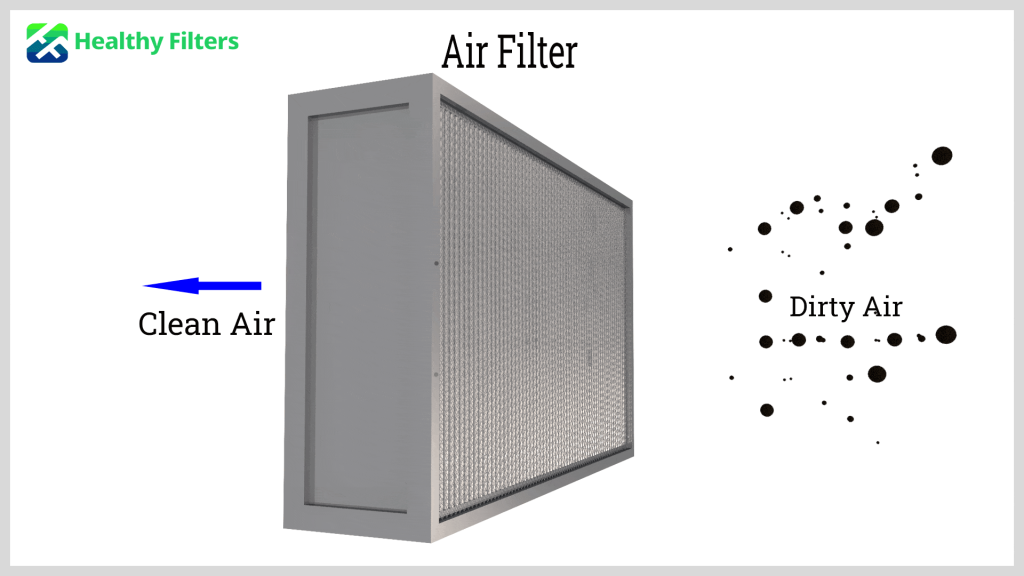

For dairy producers, hygiene is your business foundation. One contamination incident ruins batches, shortens shelf life, and damages your brand. Healthy Filters’ air quality solutions keep processing areas full of pure air—shielding high-risk steps, extending shelf life, and keeping you compliant.

Our energy-efficient, food-grade filters are rigorously tested, certified, and trusted globally. They cut contamination at the source, so you focus on making great dairy without constant worry.

Shorter Shelf Life? Bad Air Is Probably the Culprit

Whether making milk, cheese, yogurt, or butter, all dairy follows: raw milk in, finished product out. The hidden threat? Airborne yeast and mold—they’re the top culprit for short shelf life, turning fresh dairy stale fast.

Infant formula raises the stakes—one contaminant risks babies’ lives. These threats are tiny (0.6 microns on average), slipping through small gaps around equipment even if it’s spotless.

That’s why air quality must meet food safety standards, and filters need to stand up to regular cleaning.

RELATED PRODUCTS

Pre-filter, activated carbon filter, ultrafiltration/reverse osmosis filter

PROVIDE ONE-STOP SOLUTIONS FOR

DIFFERENT INDUSTRIES

Where Contaminants Lurk in Your Dairy Plant

Contamination hides everywhere. Key airborne risks:

– Harmful bacteria (E-coli, Enterobacter sakazakii—critical for infant formula)

– PAA residue from disinfectants used in aseptic processing and packaging

– General bacteria, VOCs, ozone

– Cross-contamination from floating ingredients

– Worker “microbial clouds” (we all carry germs)

Clean Air Protects Your Products & Your Team

Dairy has strict safety rules. Contamination control needs air quality management (plus temperature/humidity) in cleanrooms and filling halls—equipment cleaning alone isn’t enough.

Cutting filter costs is risky. Dryers, filling lines, slicing/maturing/packaging areas need top-tier filters to stop spoilage, recalls, and keep regulators happy.

“Budget” untested filters cost more long-term—one recall or batch loss wipes out savings.

Healthy Filters: Solutions Built for Dairy’s Unique Risks