Beverage production

Bottled Beverage Air Filtration: Safeguard Products & Brands

Want to keep your bottled beverages intact, boost shelf life, and keep customers happy? A full line of air filtration for sensitive bottling is your answer—it protects both your products and brand.

Consumers are grabbing more bottled drinks than ever, especially organic, healthy options. And the industry’s strict rules make total sense—contamination at your facility risks public health and ruins your reputation. Bottlers and brand owners can’t afford to cut corners here.

RELATED PRODUCTS

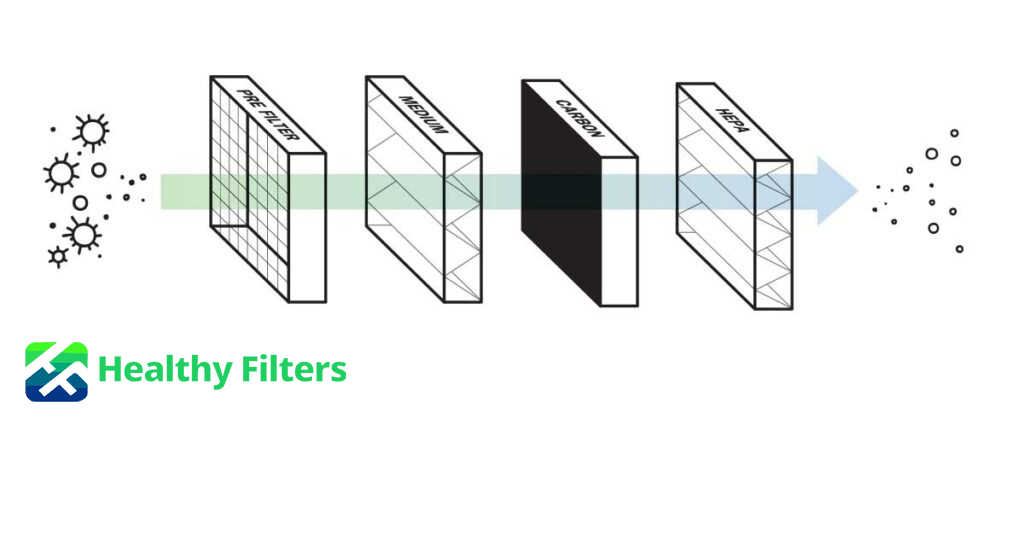

Pre-filter, activated carbon filter, ultrafiltration/reverse osmosis filter

PROVIDE ONE-STOP SOLUTIONS FOR

DIFFERENT INDUSTRIES

Certified Filtration: A Must for Aseptic Processing

Aseptic processing boils down to this: put sterile product into sterile bottles, seal with sterile caps, and do it all in a germ-free space. Whether you’re bottling water, fresh juice, or energy drinks, you’re dealing with two tough hurdles—delicate processes and humid conditions that breed germs.

Non-negotiable rule: No live organisms on or in bottles during filling and capping. That’s why HEPA filtration on conveying lines is non-negotiable—it shields open products from floating contaminants that could ruin entire batches.

What Proper Air Filtration Actually Delivers